| Well, it's the morning of April 15th, 2007 and the sun is shining. Although a mite chilly outside now the temp is supposed to rise into spring-time range in just a few hours. A beautiful morning and I am thoughly "bummed-out." I was supposed to be running in a marathon this morning but a knee injury has kept me side-lined. So I guess I will write another column and later will work on my self-designed kayak I have been building. I have a cup of hot coffee handy, have the Destin (Florida) Pass webcam open on another screen, and have a subject to address with this column. A few years ago I decided to build a sailboat. My experience with sailboats at that time was severly limited so I selected what I felt was the simplest and most practical sailboat design that I could find: a Jim Michalak AF3 . It was certainly simple and easy to build , but after overnighting on it a few times I decided that I really should have built something a little bigger, such as an AF2 or a Normsboat , but the basic concept of the boat was a good choice. After a few years I sold the AF3 and at some point will build a slightly bigger boat in the future. | | The fixed (non-adjustable) bracket that was given to me some time in the distant past. | Although some of Jim Michalak's sailboat designs such as the Normsboat and the Mayfly 16 , for example, feature mounting arragements for a small outboard motor, the AF3 did not. Being an inexperienced sailor, I felt the need for the "security blanket" of an outboard so I had to devise the mounting arrangmeents on my own. After picking over my collection of outboard motors I finally decided on (2) that I felt would be suitable for the AF3. The first was a 1945 Neptune 2hp while the other was a 1949 Gale 1.5 hp. Both engines were already in running condition and neither engine was so "collectable" or valuable that a dunking during a capsize was result in a major finacial hit. The Neptune, in fact, had a damaged crankshaft and I felt it's time was limited anyway, so it became the primary engine for the AF3. The usual mounting arrangment for outboards that Jim shows in his plans is a motor "well" between the transom and the "lazarette" compartment. I considered incorporating such a well into the AF3, but this would have greatly reduced the size of the lazarette compartment, and the bouyancy of this compartment was key to the "self-rescueing" aspect of the the AF3 design. I decided that a bracket mounting of some sort would be best. Most of you will be familar with the adjusting motor brackets so often seen on production sailboats. These brackets lift the outboard clear of the water when the motor is not in use, and lower the outboard when it is to be run. These brackets are readily available but they do cost money and they are a bit big and bulky for a boat as small as the AF3, which has a very small transom. Someone had given me a fixed bracket, one that does not adjust up or down, and I decided to use that bracket with some modifications. I could also have constructed a fixed bracket from wood, with long bolts passing all the way from the transon to the motor mounting board. | | A new motor mounting board would be made just barely wide enough to handle the small outboards chosen to power the AF3. | Jim M usually suggests mounting the rudder off-center to one side, and mounting the outboard off-center to the other side, on boats with narrow transoms. Being a traditionalist, I wanted my rudder mounted on the centerline, with the outboard off to one side, which was going to complicate matters. With only half of a very narrow transom to work with the total width of the bracket had to be minimized. One of the attributes of the (2) outboards that I selected was very narrow transon clamp spacing, meaning the the engines required a minimum of width of area upon which to be clamped. The motor bracket that I used consisted of (2) cast aluminum arms with a wood motor mounting board bolted to them. I removed and discarded the wood board and replaced it with another board witch I laminated from plywood. This new board was much narrower than the original board and in fact was just barely wide enough for the small motors to clamp to. Many other small motors, especially modern ones, would not clamp to such a narrow board. Deciding exactly where to mount the bracket was another concern. If the bracket was mounted too close to the centerline of the boat, the propeller would hit the rudder when the rudder was hard-over. The further away from the centerline the bracket was, the more likely the motor would get dunked in a capsize to that side. | | Once the proper postioning of the outboard was determined, the outboard was clamped to the bracket so the exact postion of the bracket on the transom could be found. | Another concern was how high to mount the bracket. The AF3 has a lot of "rocker" to its bottom. A lot of rocker and the small size of the boat means that a person moving forward or aft is going to cause a large change in the trim of the boat. In other words, If I walked forward into the cabin "slot," the bow was going to go down and the stern up. If I went to the rear of the cockpit, the bow would rise and the stern would drop. Both of the motors that I intended to use were so-called "short shaft" engines, meaning that they were intended for planing boats with transoms about 15 inches tall. Since the AF3's hull is not a planing hull, this measurement is not particularly useful. Here is what is important: When I walked forward and the stern rose, I did not want the propeller or the cooling water intake of the motor to come out of the water, When I went aft and the stern fell, I did not want to submerge the powerhead of the engine. Finally, I needed to be certain that there was enough clearance between the outboard and the transom so that the motor could be tilted-up, and so that the starter rope could be pulled. An outboard mounted on a bracket very low on a transom often can not be tilted-up, and often requires a "vertical pull" starter rope. The final concern was structural. The AF3's transon was not designed to take the weight or thrust of even a small outboard motor. As I also intended to use foot holds on the rudder for reboarding the boat, I built the transom much heavier than designed. I used 1/2 inch plywood instead of 1/4 inch, and I increased the size of the framing a bit. The waterlines on Jim's plans are usually marked, and utilizing a straightedge laid across the drawings I made a guess as to the vertical position of the outboard. I used the straight edge to simulate stern-up and stern-down conditions, keeping the center of the straight edge on the marked waterline at the center of the boat. Not being a naval architect, I had to guess just how far the stern would rise or fall with the weight of one or two people, but at least I had the range of motion fairly established. | | There needs to be sufficient clearance between the top of the outboard and the transom of the boat for the outboard to tilt up. | There are computer programs available that can predict the results of just such a shift in the longitudinal center of gravity, for you "geeky" guys who want a more precise prediction. . Next, I clamped the motor to the bracket (not yet fastened to the boat) to establish the position of the bracket when the motor was at the correct height. With the motor still clampled to the loose bracket, the motor was tilted-up in order to estimate the clearance between the transom and the motor. Taking measurements from the transom and rudder, It was apparent that even with the narrowed bracket there still was not enough space to one side of the rudder to mount the outboard without the propeller hitting the rudder when the rudder was put over more than about 30 degrees. I did not want to install rudder stops limiting the swing of the rudder to that side so I decided that I would just have to be carefull when motoring not to swing the rudder too much to that side. In practice this was not too much of a problem. although the rudder blade did show the signs of occasional "rudder-propeller interface." Once the desired position of the motor bracket was decided upon, I drilled one hole and bolted the bracket to the boat with one bolt and mounted the outboard to double-check the clearances. Since all seemed well I drilled the additonal (3) bolts and bedded and bolted the bracket on. While everything looked good with the boat on the "hard," I could not truly check the vertical clearance of the motor until the boat was launched. | | Bracket "arms" bolted to the AF3. The motor mounting board has not yet been added. Also shown is the fixed mast crutch: not one of my better ideas. The lower blade of the rudder has not yet been attached. | The first time on the water revealed that I had postioned the motor about as idealy as possible. Walking all the way forward in the slot raised the stern to the point where the outboard's propeller and water intake were just barely in the water. Sitting at the very stern still left the powerhead a comfortable distance above the waterline, and the motor could be tilted-up to just clear the water before the motor powerhead hit the transom, limiting the amount of tilt. Another concern in the installation was keeping the sheet from becoming entageled in the outboard, a common problem. I also needed a way to store the struck mast on the boat where it would not be in the way of rowing or other activities. My solution to these problems was not so successful. I incorporated a mast crutch into the motor bracket mounting. The crutch was not removable, and the sheet was routed through a metal ring on top of the mast crutch. Although the crutch was very handy for storing the mast, the sheet not only still became entagled in the outboard, it was also become entangled in the crutch. A much better arrangement would have been to mount the rudder off to one side, so that the motor could be moved more to the center where it wouild have been much better protected from submergence during a capsize. The propeller and rudder would have both benefited from the increase distance between the two. Don't know if this would have helped the sheet situation but it could not have been any worse.. In the end, I probably could have gotten by without the outboard motor at all. I had the oar ports and oar locks that Jim shows on the plans, and used the boat a few times on a lake where gasoline motors where not allowed, and once rowed the boat a couple miles when the old Neptune overheated. The boat was surpisingly easy to row. And I am a little bit better sailor now. Happy Motor'n click here for a list of Columns by Max Wawrzyniak  The Best Outboard Motor for a Sailboat  Last Updated by Daniel Wade June 15, 2022 The technology of sailing has remained mostly unchanged for centuries. Since learning to harness the power of wind, sailors have been transiting the world’s oceans, expanding trade routes and exploring new cultures. Although nothing more than a renewable natural resource and a single sail is needed to move a sailboat along the water, there are times when it’s important (and in our modern age, convenient) to leverage off a motor to get you where you need to go. Like any unique piece of equipment in the world of sailing, outboard motors come in a variety of sizes with features and options to fit any owner’s needs. But of course, one size doesn’t fit all. Every boat is different – even those that come off the production line at the same time – and every owner is looking for something specific when it comes to their sailboat. From the purpose of owning the boat (blue water sailing vs. racing) to the location and impact on maintenance (cold weather vs. tropical weather), an outboard motor is just one of the many elements that will define a sailboat’s function and performance. Whether you’re a new owner, or a veteran sailor, it’s important to know the basic components of any outboard motor . You should also have an idea of what you want your outboard motor to do for your size and model sailboat. Table of contents Outboard Motor SizeA larger boat doesn’t necessarily mean a larger motor. Although there are different ratings for different classes of boats, a small power plant can be more effective than a larger one. Conversely, an outboard motor can easily overpower a small boat and create unsafe conditions at high speeds. Guidelines and requirements differ between motorboats and sailboats. And while there is some overlap, these considerations apply directly to sailboats. Engine power has to do with how much water a boat displaces. For sailboats, smaller is better. If you’re a bit of a math geek, the exact formula is 4 horsepower for every 2200lb of weight. Coupled with a propeller size, which can be determined using a propeller calculator , you’ll get a rough estimate to use as a guideline to start shopping. This is a good first step, since size is essentially a fixed variable. Though it’s worth noting for those who are buying a sailboat directly from the manufacturer, that actual weight will increase after delivery – once all other rigging and outfitting has been completed. Physical size of your outboard motor is an important consideration and is directly related to the design of your sailboat. An outboard motor is made up of three parts from top to bottom: - The Powerhead – Houses the engine. The bulbous part of the motor.

- The Midsection – Houses the exhaust system. Varies in length and design.

- The Lower Unit – Propellers attach to the gearbox. Submerged when operational.

Shaft length is an important design element and should be considered when purchasing a motor. A shaft that is too short will obviously prevent the propeller from being submerged in water, while a shaft that is too long will extend the propellers too far. Not only will it decrease the efficiency of your engine, it will create unnecessary drag. Know your transom length when looking at different models. When an outboard motor is not being used, it should be stowed in its upright position. Some of the larger motors have an automated switch that will raise it out of the water, but some must be secured manually. Make sure everyone who sails with you is capable of lifting and securing the motor out of the water in case of an emergency. Outboard Motor PowerAny kind of motor installed on a sailboat (inboard or outboard) should be viewed as a tool to help with maneuvering. Although there are some very skilled sailors out there who can sail into their slip without the aid of a motor, many harbors have restrictions that either don’t allow for the use of full sails, or there simply isn’t enough room to maneuver. A motor with both forward and reverse gears helps tremendously with docking. While there is no exact correlation between boat length and total weight, the following is a rough guideline: - 1-4 HP for boats up to 20’ (approximately 1000-2000lbs)

- 4-18 HP for boats between 20-30’ (approximately 2,000-10,000lbs)

- 18-34 HP for boats between 30-40’ (10,000lbs or more)

There are some things to consider when deciding how much horsepower you need or want. Location and the type of conditions you expect you’ll be sailing in is one of the biggest factors. Heavy seas and high winds typically associated with open ocean sailing will put more strain on your engine, and in some cases overpower it, whereas an engine that is heavier than needed will add unnecessary weight when racing. If you plan on motoring for long distances, consider purchasing an engine that will stand up to a lot of use. Less HP is required for: - Boat Design – Single hull boats made out of fiberglass require less power.

- 2-Stroke Engines – This is due to an overall lighter weight engine and higher torque.

- Diesel Engines – Diesel delivers more torque because the rate of compression is greater.

- Bigger Propellers – More surface area means more water displacement.

- Location – Motoring on lakes and rivers requires less power than open ocean.

- Distance – A smaller engine is suitable for shorter distances.

More HP is required for: - Boat Design – Catamarans and heavier boats (regardless of size) require more power.

- 4-Stroke Engine – Engine weight and an extra step of compression yields less power.

- Gas Engines – The rate of compression for gas engines is much lower than diesel.

- Smaller Propeller – A smaller propeller displaces less water.

- Location – Open ocean, with tides and currents, will strain a smaller engine.

- Distance – Cover more distance when wind conditions are poor requires a larger engine.

Outboard Motor CostThere is no way to quantify how much you will pay for any given motor. But there are several costs associated with owning an outboard motor that are definitely worth considering when making your purchase. Certainly, a lager, more-powerful engine is going to be costlier than a smaller engine with lower horsepower. But as mentioned earlier, size is not necessarily a guarantee of performance and efficiency. At the same time, there’s only so much you can get out of an engine before you exceed its capability. Larger engines tend to help with resale value should you choose to sell your boat at some point, but a boat outfitted with right motor to begin with will always perform better than a motor that’s large just for the sake of it. Factor in maintenance costs and fuel when looking at models. You want to run your engine at around 90% of its max RPMs to balance proper fuel usage and with wear and tear. Making a few calls to marine mechanics to inquire about an engine you’re interested in will give you a lot of information a sales person won’t be able to give you. The good news about outboard motors is that most of them are portable, which means you won’t have the added cost of either paying a mechanic to come to you, or having to get your boat to the yard, which usually requires help from a very good friend willing to spend all day driving and sailing back and forth. Owning a boat requires constant care and maintenance, so a little knowledge goes a long way. While an outboard motor is not required for sailing, it’s a convenient addition that can greatly increase your enjoyment out on the water. Being patient and spending time researching engines will not only help you make the correct purchase but will help you take advantage of a great deal when it presents itself. Whether you sail the Caribbean, or race off the coast of California in a catamaran, there is an outboard motor that’s just right for you. Related Articles  I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing. by this author Sailboat Upgrades  Most Recent What Does "Sailing By The Lee" Mean?October 3, 2023  The Best Sailing Schools And Programs: Reviews & RatingsSeptember 26, 2023 Important Legal Info Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. Similar Posts How To Choose The Right Sailing InstructorAugust 16, 2023  Cost To Sail Around The WorldMay 16, 2023  Small Sailboat Sizes: A Complete GuideOctober 30, 2022 Popular Posts Best Liveaboard Catamaran SailboatsDecember 28, 2023  Can a Novice Sail Around the World?Elizabeth O'Malley  4 Best Electric Outboard Motors How Long Did It Take The Vikings To Sail To England? 10 Best Sailboat Brands (And Why)December 20, 2023  7 Best Places To Liveaboard A SailboatGet the best sailing content. Top Rated Posts Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL © 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy - AROUND THE SAILING WORLD

- BOAT OF THE YEAR

- Email Newsletters

- America’s Cup

- St. Petersburg

- Caribbean Championship

- Boating Safety

- Ultimate Boat Giveaway

Lightweight and Small Outboard Motors for Sailboats- By Ed Sherman

- Updated: April 22, 2019

When you’re facing strong winds and you need to get somewhere fast, it’s time to break out a small outboard such as an aluminum genny. A dependable outboard that has enough horsepower to get you to the racecourse and back, yet is light enough not to be a drag on your race results, is invaluable. Most racing sailors don’t need as much horsepower as they might think. An eight-horsepower outboard, for example, will push a 30-foot, 6,000-pound boat along at 6.5 knots. Anything bigger will weigh more than 90 pounds and isn’t suitable for lifting on and off the stern. Here’s our roundup of some of the best outboard motors for sailboats, and some help in deciphering what’s right for your boat.  We focus our attention on engines available under nine different brand names. Two of the best-known names, Johnson and Evinrude, have dropped out of the small-engine end of the market as part of parent company Bombardier Corporation’s restructuring of these two companies. Currently they’re advertising the availability of six- and eight-horsepower four-stroke models in 2003. Another dropout in the mini-engine market is Suzuki. Their smallest two-stroke is a five-horsepower unit and in the four-stroke configuration, a 9.9 horsepower. Brand and corporate shuffling aside, of particular interest is whether the companies that are building nine horsepower- and-below engines have incorporated four-stroke technology into the lower horsepower range, since it’s now beginning to dominate the mid-sized and larger outboard engine market. The answer to that is yes, to a point. Two or Four Stroke Outboards for SailboatsOutboards are either two or four-stroke engines, and the four-strokes have definitely gained favor in recent years for several reasons: they’re quiet, they use much less fuel, and they run more cleanly. Since no oil is mixed with the fuel, the classic two-cycle smokescreen isn’t a factor. In a four-stroke, the piston reciprocates inside the cylinder four times for each power stroke (that is, each time fuel combusts). Rather than opening ports cut into the sides of the cylinder, intake and exhaust valves controlled by a camshaft allow a fuel/air mix to enter the combustion chamber with the suction created by the piston as it moves inward in its cylinder. Exhaust gases are forced out of the cylinder as the piston moves outward. By carefully designing the camshaft, engineers minimize the amount of time that the intake and exhaust valves are both open, considerably reducing the amount of unburned fuel that exits with the exhaust stream. The end result? Fewer emissions and greater economy. But they do have at least one distinct disadvantage for the racing sailor, and that’s weight. For example, four-stroke engines in the five-horsepower category are about 20 percent heavier than comparable two-stroke engines of the same horsepower. The good news, however, is that only amounts to between 10 and 15 pounds, depending upon the engine. Four-stroke engines cost more, also, but the improved technology may be well worth it. If you’re totally weight and price conscious, you’ll want a two-stroke engine. But, if you think you can lose the weight elsewhere, a clean, quiet four-stroke without the hassle of mixing fuel could be the answer. In fact, Mercury/ Mariner’s newest six-horse four-stroke engines are actually 18 pounds lighter than their older two-stroke equivalents–a testament to the benefits of improved design and technology. Environmental regulations are pushing manufacturers towards four-strokes as well. Four-strokes meet emission control standards, and US Environmental Protection Agency regulations mandate that new outboard and personal watercraft engines reduce engine hydrocarbon emissions by 75 percent by 2006. Environmentally conscious sailors should look for either a C.A.R.B. (California Air Resources Board) “very-low” or “ultra-low” designator, or a specification indicating 2006 EPA compliance. How Much Horsepower Do You Need?The amount of power you’ll need depends on several key factors. The first consideration is the weight of your boat. The second is the boat’s wetted surface. Full-keel boats not only weigh more but also have more surface area to push through the water. My rule of thumb here is to start with a two-horsepower engine for small centerboard and keelboats less than 1,000 pounds, and add one horsepower for every 1,000 pounds of displacement. For more exact, albeit complex formulae, I suggest The Propeller Handbook by Dave Gerr (McGraw-Hill 2001). Compare your boat’s dimensions against what existing classes have found to work; for example, a Melges 24 at 1,650 pounds is typically rigged with a three-horsepower short-shaft engine, while a J/80 at 2,900 pounds can still squeak by with a long-shaft, three-horsepower engine. A 1,790 pound J/22, on the other hand, typically uses a four-horsepower long-shaft engine. On the larger end of boats using outboards, you’ll find the outboard version of the J/29, at 6,000 pounds, requires a 7.5-horsepower long-shaft engine. If you are intending to do some cruising, or even long deliveries to regattas, an option that’s available on some engines is a high-thrust propeller. On larger boats, this option can save weight over a bigger engine and really make a difference when trying to punch through a strong tide or headwind. High-thrust props cost more and are less fuel efficient–but they can save weight and give you more power. Once you’ve determined how big an engine you’ll need, the next step is to begin comparing features in the given horsepower range you’ve selected. There are nine manufacturers included in our roundup, but some of their brands are identical products with different labeling. In the smaller sizes, the Mercury and Mariner brands are identical. As for the Nissan and Tohatsu engines, Tohatsu builds them all. Yamaha, Suzuki, and Honda all offer competitive products as well, but they’re all independent brands. What to Look For in Lightweight Outboard MotorsIn the small engine sizes, specific features to look for can be reduced to several key items. For some, having an integral fuel tank will be important. The smallest engines have integral tanks that hold only a quart or two of fuel–good enough for an hour or two of operation. No manufacturer lists fuel consumption because the size boat the engine is pushing and the wind and wave conditions vary widely. Compare the size of the tanks, and whether you can attach a remote tank for longer trips. The extra weight and space of a separate fuel tank will be a burden on smaller ultra-light boats. The availability of long- and short-shaft versions in the horsepower size you need is also important. Honda for example offers 20 and 25-inch transom height (long or short shaft) right down to their smallest BF2 (two-horsepower) model. Mercury and Mariner only offer a 15-inch short-shaft version on their 3.3- and 2.5-horsepower engines. Shaft length is measured from the top of the bracket to the tip of the shaft–make sure your shaft is long enough to position the propeller and cooling water intake deep enough below the waterline to avoid cavitation when the boat pitches through waves. Other specifications that are worth comparing are whether the engine is equipped with a simple forward and neutral gearshift or if the unit has a full functioning forward-neutral-reverse gear unit. If you’re going to be doing long deliveries to regattas, or in the larger sizes for a racer/cruiser configuration, consider whether or not a charging system is part of the engine package, and if so, it’s output. Will it be adequate to keep your battery recharged and power things like a tiller pilot and running lights? Also, on the larger engines check to see if electric starting is available, or offered as a standard feature. Having it can be the difference between pain and pleasure. If you are racing in a strict one-design group, check any class rules that apply to outboard engines. Issues related to brackets, storage of the engine and/or alternative weight might be issues, so be sure to check with your class before making any final decision. Ed Sherman is the author of Outboard Engines, Maintenance, Troubleshooting and Repair, International Marine/McGraw Hill and a contributing editor to Sailing World. - More: Accessories , clothing , Sailing Gear

Comfort Rules with Mustang’s Minimalist Buoyancy Aid Smart Polars Are Here Reproofing May Be Required Wingfoiling Gear: A Beginner’s Guide Mistakes And Misfires On the Final Day of Cup’s Preliminary Regatta Emirates Team New Zealand Remain the Bullies of Barcelona Start-Box Sparring in Barcelona on Day 2 of Preliminary Regatta Real-time Wind Overlay Feature Added to Cup Broadcast - Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Backyard Dory Backyard boatbuilding and other adventures.  I’m getting old and can only row so far for so long. My two daughters, Samantha and Allie, haven’t ever rowed anywhere before. Because of this, we decided to cut a giant hole in the bottom of our beautiful boat so we can install a small outboard. This step of the build was certainly the most nerve-racking. We put so much effort into ensuring the boat was built tight and leak-free; what sane person would cut a giant hole in a perfectly good boat?! Alas, we were determined to have outboard power for our dory. So we schemed a way to add a motor well. Before doing so, however, I scoured the internet for the best way to install a motor well, focusing on sizes, locations, depths, etc. It was obvious from my research there are two motor well camps: those that find them useful and those that don’t. During my searches, I came across side-mount outboards, which seemed like a good idea, but I was concerned because the waters where I’m going to use the boat will get relatively rough and I didn’t want to have a 40 pound outboard hanging over the side of the boat. I liked the idea of having the boat inboard the hull, on centerline, and easily reachable. As such, I bought an outboard. I figure this 3.5 horsepower Tohatsu will be more than enough power, and it was just a few bucks more than the 2.5 horsepower and the same engine that just rev’s higher, so I splurged. At 40 pounds, I can easily move it around, so it seemed like a fitting choice. I wanted to have an outboard with a larger external fuel tank, but seeing as I won’t have to run it at full throttle, I imagine the small internal tank will last me long enough between refueling.  The next decision was whether or not to build a motor well that allowed the outboard to kick up into the well. I toyed with the idea, but in the end, my dory just seemed too small to take up so much space with a kick-up outboard well, so I didn’t build it that way. Plus I figured my dory won’t go faster than about 4 or 5 knots, so even if I run into something submerged or hit a shallow bottom, I’m not going to break anything (other than maybe a plastic propeller that I can easily replace). So I kept the motor well simple: a squarish hole in the bottom of a perfectly good boat with raised sides that kept the water out and the outboard supported. Having the outboard on hand really helped this process, and I pulled measurements directly from the motor as I progressed. The design plans I had did not have specific well measurements, so I was truly building from scratch at this point. Not a huge deal and it was easy to piece things together as I went along. This outboard spins 360 degrees, so I made sure that I took measurements with the outboard in a multitude of positions so that I had enough clearance to spin it in a full circle. That made for a little larger of a well than if I didn’t use a 360 degree spinning outboard (i.e. used one with reverse gear), but not too much larger. I decided to put the outboard just behind the fourth frame of the boat. Aesthetically, it seemed like the best spot, so I went for it. Measuring carefully, I transcribed the dimensions I needed from the actual outboard onto pieces of plywood that would serve as the sides of the motor well. I decided to make the back of the motor well at an angle in order to minimize the amount of water that either splashes or plows its way up the backside of the well.  Once the two plywood side pieces were cut, I sanded them as one unit so they were exactly the same. The last step for the sides was to make sure the bottom curvature of the boat, or rocker, was accurately transcribed onto the bottom edge of these side pieces. With the rocker roughly drawn to shape, I cut and sanded the bottom portion of these side pieces so that they conformed to the rocker on the bottom and sat level and plumb at the top.  With the side pieces in position based on my end-to-end measurement of the outboard’s lower unit as it rotated through 360 degrees, I spaced the side pieces appropriately and drew the lines onto the bottom of the boat that marked the hull cut that would soon be the opening for the motor well. I can tell you that I sat and stared at these lines for some time before I even plugged in my saw. Then I measured them again just to be sure. Then I broke out the saw. And then I measured them again!  And the moment of truth was upon me. Time to cut a giant hole in the bottom of my perfectly good dory. I utilize a jigsaw and an oscillating saw to carefully cut along my markings. Drumroll please…  With the drama of the hole being cut behind me, I pressed on with the installation of the motor well. Using spacer pieces of scrap lumber and several clamps, I positioned the motor well sides into place and made measurements for the front and the back pieces of the well. Once measured, I cut them out, sanding them to fit, and readied them for installation.  With the front and back pieces ready to be installed, I applied them, one at a time, bedding each in a solid mix of thickened epoxy. Once the epoxy set, I removed the temporary bracing and the motor well was complete!  I ended up adding a 2×4 to the front of the upper edge of the motor well so the outboard had a little more substance to bite into when I tightened down its mounting screws. You can see the addition in the pictures below when I test fit the outboard. It ended up fitting perfectly and I can only imagine the smile on my face finally having my mechanical oar in place! Yes, I did sit in the boat with the motor installed and made motorboat noises!  With a finished motor well, it was time to finish the fiberglass work and then paint the inside of the boat ! Click each area to see how Elizabeth Lynn ends up! 4 thoughts on “Motor Well”Hi Kevin, I have a client that wants a motor well in his Nova Scotian 4.9 Grand Banks Dory I came across you building blog and you have done it successfully, I will be fitting a Suzuki 2,5 Hp Is there any possibility for you to send me your dimensions and angles of your well. I enjoyed looking at your build you have some good techniques. Kind regards Paul Doesn’t appear to have room to tilt up the prop! Tom – you are correct! No room to tilt up the prop; I didn’t want to take up any more space than I had to inside the boat. My solution was to get an outboard that only weighs 40 lbs. If I need to move the motor, I simply unscrew the transom clamps and pull the motor out of the well and into the boat! Pretty easy and has worked well. Paul – I’m not sure if you will ever check this again since it has been almost 2 years since your comment, but if so, please reach out again and let me know the best way to send you the information you requested! Leave a Reply Cancel replyYour email address will not be published. Required fields are marked *  - Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Sailboat Design and Construction

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Well Mounted Outboard - Add to quote

- Prop More likely to be in the water in a seaway.

- Less likely to be stolen

- Less likely to be damaged backing up

- May be easier to reach

- Takes up locker space

- Harder or impossible to take out of water

- Turbulence around hull hole slows boat down.

- May Smell More

sailingdog said: Advantages: Engine head is more protected from elements and salt water. Engine less likely to get swamped Click to expand...  davidpm said: I would like to know all the advantages and disadvantages of bracket mounted vs. well mounted outboards. Well Advantage over Outboard Prop More likely to be in the water in a seaway. even with a long or Xlong shaft they still come out of the water, depending on conditions Less likely to be stolen maybe Less likely to be damaged backing up LOL true May be easier to reach True and that's could be a biggie Well Disadvantage over Outboard Takes up locker space If you have a well, the space is already lost, also depending on transom, most likely worthless space anyhow Harder or impossible to take out of water Not at all Turbulence around hull hole slows boat down. not noticable, and only a 1 knot loss with motor in place under sail May Smell More True unless you get one the exhaust thru the hub, then not so much What did I miss or get wrong? Click to expand... The boat I had, the OB set in the well in such a way that the head and it's controls were easy to access. steering was done by the tiller, so there was no need to move the head, just the pull start, forward and reverse, choke and throttle was all you ever needed to touch. Mine was easy to lift out, but I knew some people perfered motor lifts When we first got the boat the PO had a transom mount and it was a PITA to operate it, so I cleaned up and redid the well.............big difference in the two mountings My portager had a transom mount, and while it worked nicely, unless you were on the port side with the motor it was awkward to maneuver. Pulling up to a dock to starboard was a real pain. The Ariel has a well, and it's positioned in such a way that the motor controls can be easily reached from either side, so it's no problem docking at all. I don't think the space could be considered as wasted, the well gives you a place to store fuel and a battery with the motor while keeping it out of the cabin or anywhere that the fumes could get into living space. Also keeps the weight of the motor closer to the center of the boat, not hung way out where it has a lot of leverage. The only drawbacks I really see is the steering, you can't crank the motor off to the side to push the stern around, and you are often limited in physical size, especially when considering a 4 stroke. And as stated earlier, it's also more attractive to see a nice clean transom, and less attractive to thieves, simply because there's more work to get them out. Ken.  I will not own another boat that has transon mount outboard. It will be stolen. Mine was last Sunday night. Not even a new motor. 1982 Johnson 7.5 hp 2 stroke. Did you have a lock on it?? Bolt cutters A lock only keeps the honest man honest.  Ours is on a bracket. (locked with a cable) The wife tells me stories of starting the motor in the well of her family's Coronado 25. OY!!  Ouch, that sucks. One of the downsides of being at a marina, you have to lock your stuff up. To the OP, also think about what kind of support you need on the transom for your outboard. I'm starting to get some gelcoat cracks from the stresses. I plan to re-inforce the transom from the inside when it warms up a touch. Thank you all. As usual we have a pretty good summary of the issues. Thanks SD for the post and image. I will buy one just as soon as I can afford another motor. I've seen them cut the motor, lock and transom right off the boat!! Bastids!! WouldaShoulda said: I've seen them cut the motor, lock and transom right off the boat!! Bastids!! Click to expand... Greetings, I have an 8 hp long shaft Honda weighing 84 lbs. in the well of my Cape Dory 25. Giving the opening at the bottom, there is no way that the well will flood. To insure adequate air, the rear mounted hinges are blocked up. The big downer is that the engine is too heavy for my 73 year old bones to lift. Presently, I am assembling boom mounted tackle that will hopefully solve that problem. What I do not like is the engine tiller sticking out of the access which prevents all but minimal steerage. I understand that Nissan's removable tiller arm solves that problem. Another problem with outboard motors for sailboats is that the correct prop pitch is hard to find. You want a 6" inch pitch, while most have 8 to 9" which makes the engine labor. Dick  My previous boat (Bristol 24) had an outboard well. The boat was much more attractive with the outboard hidden. The well also kept it hidden from sight by thieves. Occasionally it would starve for oxygen, and I would just pop the hatch slightly open to allow more air in. The well made the engine noise much quieter. The biggest disadvantage (very big IMO) was that the corrosion was much worse. The shaft and lower unit were destroyed after about 4-5 years. On some boats, the well is large enough that it is easy to lay the outboard in sideways when the boat is not being used. That way, the shaft is not submerged in salt water for 7 months straight.  Davidpm, I had a Coronado 25 for 10 years sailing San Francisco bay and out the Gate, some nasty conditions at times. The Coronado has a lazerett type of well which also provides room for 2-6gallon cans of fuel. Started out with a 6 hp 2 stroke Evinrude which has OK but lacked the thrust for going through the short high chop. Went to a 15hp 2 stroke Evinrude which was the same size as the 9.9 hp, more than enough power. Ventilation can be a problem at times depending on the direction of the wind. Drilled some small holes near the top of the engine cover which helped. The hatch to the well always had to be open. With a 4 stroke this may not be as much of a problem? Hardly ever with the long shaft was there any cavitation. If I was to do it over I would get the electric start, much easier to start and would help to keep the battery charged. Can't imagine having one mounted on the transom for anything but very calm conditions. Dabnis locks on outboards My outboard(8H.P, Yamaha) has a cable lock with a bar lock and is transom mounted(all heavy duty stainless). Short of cutting the motor from the mount good luck stealing it. Still would like an inboard but on a C@C 24 not enough boat to carry the weight and bulkiness. Everyone i know with a well mounted outboard finds them to be a hassle, awkward and regret having it. A good idea but not to practical. Got some good news today. Seems that a number of people emailed and called me early this morning that they had spotted my motor, that was stolen, on craigslist. One even reported it to the cops in Port Lavaca before they called me. As soon as I get it from the cops I'll be putting the lock on it that SD suggested and moving over to a slip that is not so easy to access. Again thanks SD for posting the lock. Stazo Lock Smartlock It looks good BUT the diagram at one website makes it appear that it uses a circular lock/key. They can be defeated quite easily, at least the ones I have used / picked. Hopefully They use another type. mdbee said: It looks good BUT the diagram at one website makes it appear that it uses a circular lock/key. They can be defeated quite easily, at least the ones I have used / picked. Hopefully They use another type. Click to expand... Top Contributors this Month The Dory ShopLunenburg, Nova Scotia, Canada | (902) 640-3005 | [email protected] - Outfitting /

- Motorization

- Sailing Rigs

- Accessories

- Dory Merchandise

Traditional tip-up motor wellThe traditional arrangement for adding power by outboard, the tip-up well is a long rectangular box fitted to the bottom of the boat, on which a small horsepower outboard can be hung and into which the prop and shaft can be swung up, safely out of the way when you wish to beach or trailer your boat.  Custom-built upright motor wellSince cutting a hole in the bottom of a boat does reduce a dory's freeboard - that is, the boat above the waterline - and installing the old-fashioned tip- up well also takes up a certain amount of interior space, there are those who prefer to keep the footprint of their well as small as possible. For these folks, we offer what we call an upright well, custom-built to accommodate the specifications of their particular outboard. The one downside is that in this arrangement, the motor must be physically lifted or otherwise raised out of the well for the boat to be beached or trailered; it can't be tipped up. We’re happy to discuss which option suits you best. Inboard enginesThe most authentic way to power our larger dories is via an inboard engine. While the cost and availability of outboards has made this less common in recent years, we remain keen to assist clients with this arrangement in mind. Whether you're thinking of an authentic gas engine like the Make and Breaks manufactured under the brand names Atlantic and Acadia here in Nova Scotia, a nice little diesel unit or one of the new electric motors, we're happy to assist.   20′ Banks Fishing Dory, USCG – Outboard Motor WellToday I nearly worked all day calculating the outboard motor well. What is left to design and build is the removable tunnel baffle that will start at the bottom “V” of the motor well and come up to the bottom of the rear notch. This will force the prop wash to propel the boat naturally. The large notch cutouts on each side of the well will allow the motor to swivel to the port and starboard so the boat can be maneuvered with ease. - The Bass Fishing Archives Team

- How BFA Started – Version 2012

- How BFA Started – Version 2021

- Privacy Policy for Bass Fishing Archives

- Breaking Through

- Sticks of the Past

- Electronics

- Friday Finale

- Lady Anglers

- Memorabilia

- Old Bass Boats

- Old Bass Magazines

- Old Tournament Organizations

- Short Strikes

- Tackle History

- Gimmick Bass Tackle

- Technique History

- The Writers

- Throwback Thursday

- World Series of Sportfishing 1960 – 1968

- Bassmaster Tournament Records and Winners

- Book Reviews

- Bassmaster Tournament Patches

- Historic Bass Fishing Pics

- Bass Boat Catalogs

- Bass Buster

- Bill Norman

- Crankbait Brand

- Crazy Head Lure Company Charlie Brewer

- Eppinger Dardevle

- Fred Arbogast

- Helin Tackle Company – Flatfish

- Lew Childre

- Mister Twister

- Richardson Rod and Reel Co.

- The Out House

- Whopper Stopper

- Wright & McGill

Select Page - Montgomery Ward Outboard Motors and Boats – Part 3

Posted by David Smith | Aug 26, 2024 | Old Bass Boats , Tackle History | 0  Today, in this series finale, we’ll take a brief look at the Montgomery Ward Outboard Motors and Boats in the 1949 Fishing Catalog. In Part 1 we looked primarily at the fishing lures offered by the retail giant. Part 2 scanned the rods and reels offered, with special mention of the Montgomery Ward Sport King brand. In this, Part 3, we’re going to wrap up by taking a quick walk-through of the outboard motors and boats Montgomery Ward (MW) sold. There is more to this catalog than the above-mentioned categories. The publication is actually labeled as the company’s Fishing and Camping Catalog, but the emphasis is really on fishing, with the camping products being a complement to fishing. So, while there are tents, sleeping bags, camp stoves, knives and more, we won’t be looking at those. We also won’t be looking at other fishing gear like landing nets, inboard engines, rain gear, waders, etc. Just as Sport King was the Montgomery Ward brand of fishing lures, rods and reels, so too the company had their own brand of outboard motors and boats: Sea King. And just as they did with Sport King, they had several other companies manufacture Sea King motors and boats throughout the company history. Montgomery Ward sold Sea King outboard motors from 1931 or 1933 (there is some confusion as to the exact date) to 1986. Prior to the introduction of Sea King, they used the names Hiawatha and Neptune to designate their brand. Hiawatha was the MW brand manufactured by the Spinaway Boat Motor Company beginning sometime in the 1900s until 1916, at which time production switched to the Caille Perfection Motors Company in Detroit. The Hiawatha name continued until, I believe, around 1933. Caille also produced the MW Neptune line, which was introduced in 1926. At the time of this catalog, 1949, Sea King motors were being made by Gale Outboard Motors. Gale Products was part of the Outboard Motor Corporation (OMC), which was the company that made Johnson, Evinrude and several other outboard motor brands. The story behind the formation of OMC is fascinating and somewhat convoluted, and is something we’ll tackle at a later date. Gale had production facilities in Illinois, Wisconsin and Ontario. In any event, Gale was the primary manufacturer of Montgomery Ward’s Sea King line from 1941 to the early 1960s (1963?). Other companies produced Sea King before and after Gale’s production. Gale Products has an interesting history as well. They started out making refrigerators for companies like Mayflower and Speed Queen. After they switched to outboard motor production they achieved even greater success, making over a million outboard motors. In 1947, two years prior to this catalog, Gale sold well over a quarter-million motors, more than all other outboard motor companies combined. In the 1949 Montgomery Ward Fishing Catalog the Sea King entries begin with the 1.5 hp and 3.0 hp Standard models. These cost $62.50 and $83.50 respectively ($2 more if you lived in Denver, Fort Worth, Portland or Oakland). That would be $826 and $1,103 in today’s money. But you could also put a fraction of that total down and pay in monthly installments. For the 3hp motor you could put $17 down and pay $7 a month. These small engines were designed for canoes and rowboats.  David SmithDavid Smith has worked a number of diverse occupations, including artist, cook, writer and college instructor. It’s been said he has a shelf life when it comes to 9-to-5 work. But one thing he’s never tired of is fishing and the outdoor life. Currently living the dream in northern Wisconsin, David fishes several times a week, year-round, on both open and hard water. And when he's not wetting a line he can often be found in his workshed carving ice fishing decoys or wooden lures. Check out his foraging website (http://www.creativesustenance.com) and his fishing-centric Instagram page (https://instagram.com/stumpjackoutdoors/). Having a passion for collecting vintage fishing gear and ephemera, he’s proud to be a small part of Bass Fishing Archives, lending a hand in documenting the rich history of bass fishing. Related Posts Eppinger and Johnson 1940August 14, 2023  The Mann’s HardwormJanuary 9, 2023  Garcia Rebates 1979May 2, 2023  Graphite too Expensive?July 18, 2022 Leave a reply Cancel replyYour email address will not be published. Required fields are marked * Please Support the Bass Fishing Archives by Purchasing a Subscription to "The History of Sportfishing" Documentary, featuring Two 1-hour Chapters on Bass Fishing History written by Terry Battisti  - Bass Tackle Catalogs

- Let's Look Back

- Sunday Sonnett

- Uncategorized

- World Record Chase

Recent CommentsRecent posts. - Skeet’s Beginnings

- Pro Bass Anglings’ Most Famous Brand

- Incredible Big Bass Column 1948

- Berkley Terminal Tackle 1966

Posted 2024-08-31 13:31 Contact Information: 1996 Smokercraft Pro Mag boat & 96 Yamaha 30 hp motor - $2,500 (Little Suamico) QR Code Link to This Post post id: 7780647269 posted: 2024-08-31 13:31 ♥ best of [ ? ] refresh the page. 1996 Smokercraft Pro Mag boat & 96 Yamaha 30 hp motor - boats - by...1996 Smokercraft Pro Mag 16' 6" Boat with live well, bilge, power anchor front, new carpet. 1996 Yamaha 30 HP Motor. New tires on trailer Log in or Sign upYou are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser . outboard motor wellDiscussion in ' Boatbuilding ' started by J Ralph , Oct 1, 2004 .  J Ralph Junior MemberI am looking to build a wood skiff for a mooring tender,and I would like to have the outboard motor in a well...anyone have any plans for something like this? Thanks  carolina skiff scottyi'm in the same boat -- ha. have a 16' wooden skiff i've stripped to the hull and am rebuilding. i've seen these motor wells, but not sure what value they add. they just seem to clutter the stern and make it more difficult to (a) run steering/throttle cables to the console (b) allow water in the cockpit to drain back to the transom, and out the drain hole/scuppers. Someone willing to refute me, and tell me why motor wells are necessary? motor well check this out -- http://www.glen-l.com/designs/outboard/motorwell.html question --- i assume this motor well allow waves that may crash over the stern to drain back out the cutout where the outboard bracket rests -- what about water in the cockpit? where would that go, since this covers up the drain hole/scuppers? the kind of well I mean would be 2-3 feet forward of the transom.It's purpose would be more for protecting the motor as the skiff would be tied up at a pier with 7or8 other skiffs,and they are always getting smashed up when it gets windy.Also,it would just be a small(2-5 hp.)outboard with a tiller arm...no steering cabels...any ideas??? J oh yeah....also it would have no scuppers...just a floor and a bailing bucket!  mark j New Memberthe forward motor wells i have seen are mainly used for the purpose of nets. its easier to haul nets without an outboard sticking up to become entangled in. this is more for protecting the motor from other skiffs and the dock THAT motor well You need to check out a design called a Simmons Sea Skiff. I think Old Wharf Dory Co. makes some. It's a carolina coastal design with an "internal" motor well to (as above mentioned) keep the stern clear for hauling nets. GO SOX! I'll try to find that on the web and see if I can get some plans.Was at game 5 at fenway park for ALL 14 innings.....what a game....can't wait for Shilling to take the mound sunday!  joseph R Whaley Guestguest Speaking of skiffs with motor wells, they are commom along the east coast of nc. they work great for running gill nets and small shrimp twrals also great for oystering and claming a verry good work boat. I have owned and worked about six of these during the past years.if I was in the markett for one I would look around morehead city or Harkers Island. NC. thanks for the info....I was looking to build a small one(around 12 feet) just for a mooring skiff  19 Glasply I/O to Outboard Positioning outboard on a pontoon Boat plans change from outboards to inboards, what work needs to be done? Bilge Ventilation On An Outboard Boat Rascal - Mahogany outboard runabout Aluminum outboard mount design Electric Motor as Wooden Boat Option I'm new - looking for plans for a 16 foot aluminum boat with a tiller motor balboa26 converstion to motorboat Sailboat concessionária to motor boat- No, create an account now.

- Yes, my password is:

- Forgot your password?

- 2024 BOAT BUYERS GUIDE

- Email Newsletters

- Boat of the Year

- 2024 Freshwater Boat and Gear Buyers Guide

- 2024 Boat Buyers Guide

- 2024 Water Sports Boat Buyers Guide

- 2024 Pontoon Boat Buyers Guide

- Cruising Boats

- Pontoon Boats

- Fishing Boats

- Personal Watercraft

- Water Sports

- Boat Walkthroughs

- What To Look For

- Watersports Favorites Spring 2022

- Boating Lab

- Boating Safety

- Ultimate Boating Giveaway

Boat Test: 2024 Hurricane SunDeck 2600 OB- By Alan Jones

- August 30, 2024

The Hurricane SunDeck 2600 OB features a symmetrical layout with twin reversible-back stern lounges. Flipped forward, the backrests allow those facing aft to lounge and watch swimmers or enjoy the sunset. Flip them aft, and the more-upright backrest position proves ideal for those who want to face forward.  Interior and AccessoriesUp front, the bowrider seats offer the perfect amount of recline. We liked the playpen option that fills the bow with cushions. Because there’s a sterndrive version of this boat, the outboard iteration nets a massive 2-foot-deep compartment from the empty engine space. In addition to underseat storage, a roomy head compartment with a freshwater sink is also ideal for storing large items, if the toilet won’t be used. We tested the SD 2600 in Havasu City, Arizona, under a blazing sun. Yet, we kept cool, thanks to the optional wakeboard tower ($19,028) with its expansive, black mesh-fabric top. The top is power-actuated, rated to 55 mph, and remains level when lowered to limbo under low bridges.  The helm on our test SD 2600 featured dual Simrad NSX 3007 GPS displays ($3,473), along with the controller for the standard Fusion six-speaker stereo system, which can be upgraded to a dual-amp system with two additional stern speakers and remote as well as a subwoofer ($556). A premium JL Audio system is also available. The helm seats have standard electric cup-holder coolers. Other notable standards? A stern shower and wireless phone charging stations.  Our test boat was powered with a Honda 350 hp outboard . The smooth-running new V-8 from Honda displayed its engine data through the Simrad display while we recorded its speeds. The Honda 350 outboard proved smooth in cornering and held its power and bite in turns. Deck boats usually can’t boast of seakeeping ability, but the SunDeck 2600 OB sports a 19-degree deep-V hull, which helps it slice through the chop. At cruise speeds, the robust hull rides slightly bow-up at 3 to 4 degrees of running angle, and although Lake Havasu was pondlike on test day, its design inspires confidence for big-water cruising.  How We Tested- Engine: Single Honda 350 hp V-8

- Drive/Props: Solas 16″ x 18″ 3-blade stainless steel

- Gear Ratio: 1.79:1 Fuel Load: 54 gal. Water on Board: 0 gal. Crew Weight: 750 lb.

High Points- The large head compartment with a freshwater sink is a huge plus for families with kids.

- The SD 2600 now has a windlass option ($4,494).

- The base boat is well-equipped with a six-speaker Fusion stereo and a Bimini top. Eight hull-color options are available ($695).

- The Oasis Cognac vinyl-seat option can get hot.

- The rear-facing stern seats can’t be used when cruising.

- The swim platform is small compared with the one on the sterndrive version.

Toughest CompetitorThe slightly longer Sea Ray SDX 250 is the smallest in its deck-boat line. It also has reversible stern seating, a slightly larger swim platform, and a heavier, deeper-V hull with 21 degrees of deadrise. Its maximum available Mercury-only power is a 300 hp V-8 Verado, which pushes its price to $138,070. Pricing and Specs| | $145,176 (with Honda 350 hp V-8) | | | 26’5″ | | | 8’6″ | | | 2’4″ | | | 4,370 lb. (dry) | | | 19.36 degrees | | | 66 gal. | | | 400 | | | Single Mercury, Yamaha, Suzuki or Honda |

Speed, Efficiency, Operation Hurricane Boats – Elkhart, Indiana; hurricaneboats.com - More: 20-30ft , 2024 , boat tests , Boats , hurricane , October 2024 , outboards , Runabouts

Boat Test: 2024 Grady-White 231 Coastal Explorer Boat Test: 2024 Brabus Shadow 1200 Sun-Top Boat Test: 2024 Monterey Elite 30 Boat Test: 2024 Fjord 39 XP 2025 Alumacraft Competitor 205X 2025 Alumacraft Trophy 185X - Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Many products featured on this site were editorially chosen. Boating may receive financial compensation for products purchased through this site. Copyright © 2024 Boating Firecrown . All rights reserved. Reproduction in whole or in part without permission is prohibited. - Spirit 1.0 Plus

- Spirit 1.0 Evo

- Pod Drive Evo

- E-Series Battery

- G102-100 Battery

- Find a Dealer

- Have a Dealer Contact Me

- Product Registration

- Support Center: FAQ & Guide

- Video Tutorial

- Download Center

- Performance Bulletins

Outboard Motor Battery: What Size Do I Need & What’s Best for My Boat?New to boating and trying to figure out what outboard motor battery you need? However, you might get overwhelmed by the vast choice of outboard motor batteries in the market. To name just a few: marine batteries, lithium batteries, lead-acid batteries, AGM batteries, deep cycle batteries, starting or cranking batteries… And all outboard motor batteries are available in various volts, sizes, brands, etc. The more you search online, the more confused you might be. You are not alone! Here we will explain all your confusion in a simple guide. If you are one of those who are trying to figure out the battery needs for your boat (types, sizes, etc), read this post to find quick answers. Besides that, you will also learn about outboard motor battery wiring and charging in minutes. Table of contents: Outboard Motor Battery TypesElectric boat motor battery sizes, best outboard motor battery, outboard battery wiring, outboard motor battery charging. - FAQs About Outboard Batteries

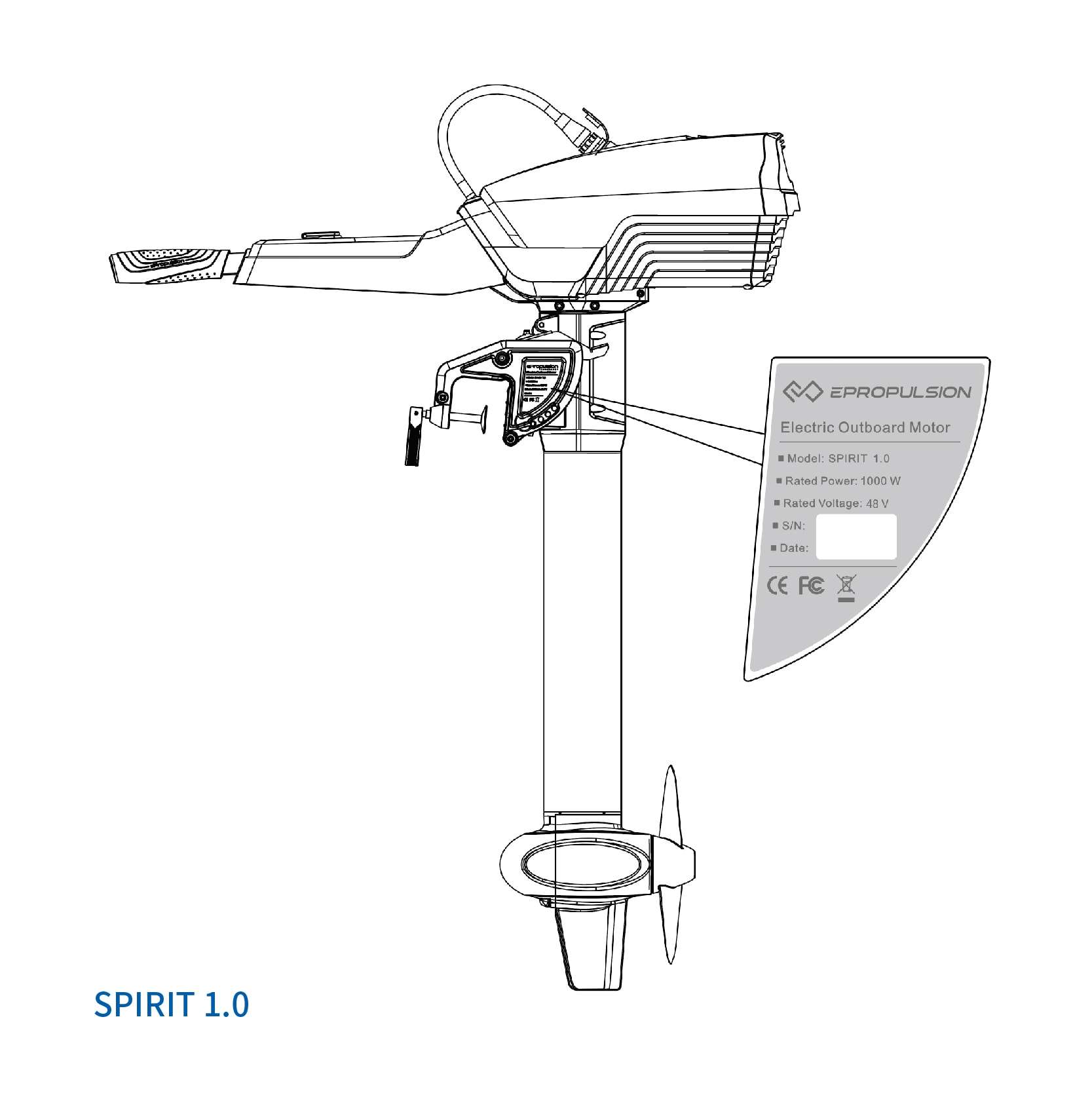

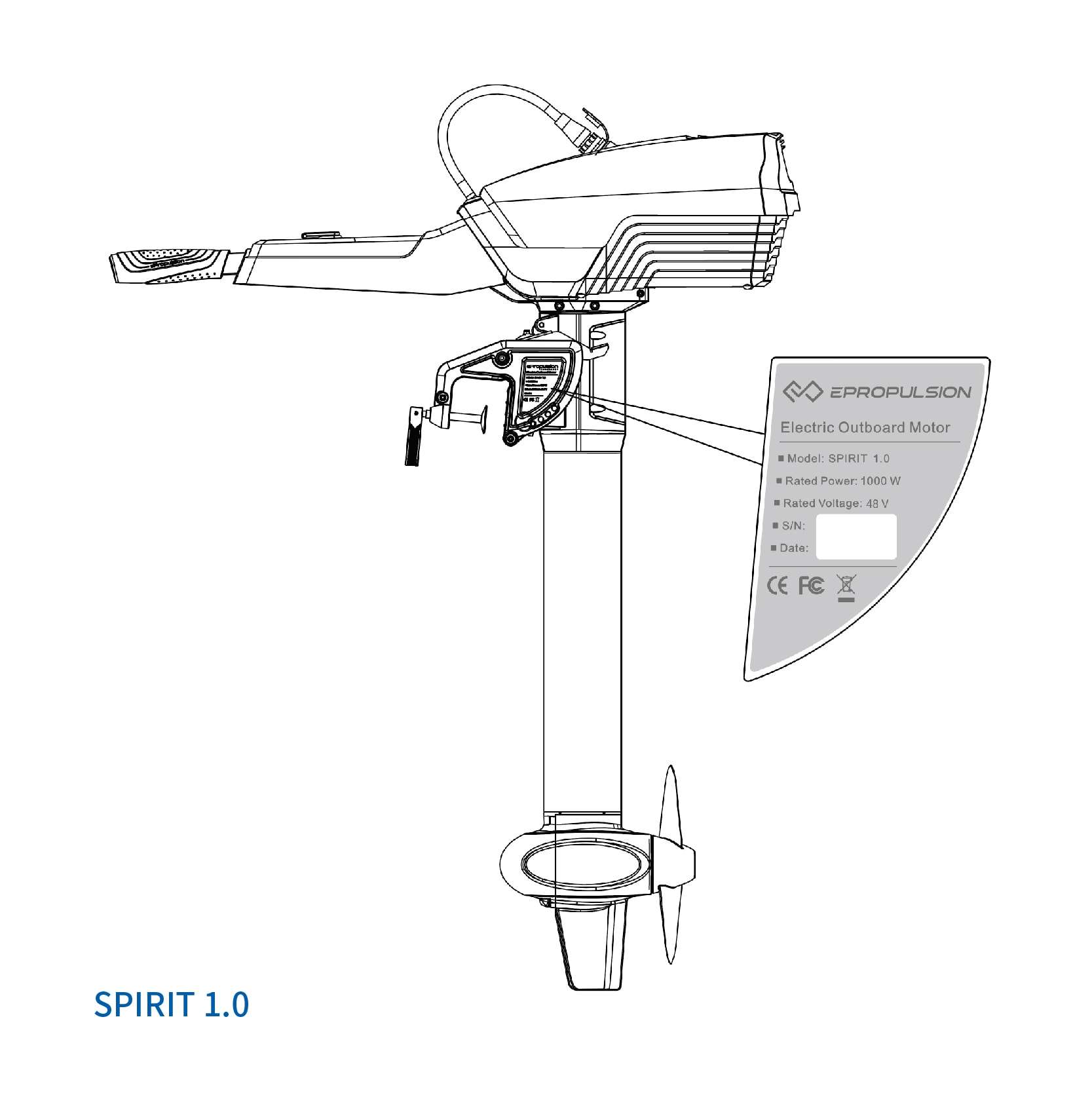

What kind of battery do I need for an outboard motor? You might have seen outboard motor batteries with confusing labels. In fact, they are categorized according to their purposes and chemistry. 2 Types Based on PurposesBasically, all outboard motor marine batteries serve two purposes: starting the engine or running the electrical load onboard. This divides outboard motor batteries into two types. As the name implies, a starting battery (or cranking battery) is ultimately designed to start the engine. This kind of outboard motor battery comes with high CCA values, providing high current surges and cranking amps to start your engine. If using the wrong battery that’s not designed for a starting (or high-power) application, you will have a high chance of starting a fire in the voltage regulator and killing the battery. By contrast, a deep cycle battery is made for discharge and supports intensive cycling. It provides rechargeable power for many cycles, ideal for running electric outboard motors, trolling motors, and electronics onboard. Compared with starting batteries, deep cycle batteries are more expensive and heavy, but they are perfect for powering stuff without an engine running. Key takeaway: Basically, the kind of battery you need for an outboard ultimately depends on your purpose. If you’re looking for a battery for an electric start outboard motor (vs pull start) , the starting battery is what you want. However, if you own an electric outboard or trolling motor, you should use deep cycle batteries ( LiFePO4 is recommended). 4 Types Based on ChemistryYou will find four kinds of outboard motor batteries if you look at their chemistry inside the cells, namely flooded batteries, gel batteries, AGM batteries (advanced lead-acid batteries), and lithium batteries. Among them, lithium is a HUGE upgrade in battery technology, and there are a great number of advantages that people run to lithium (especially LiFePO4) for their outboard motors: You can fully discharge the battery cells every day (almost 100% vs 50% for AGM) without killing them. Moreover, they can recharge 2k-10k times vs 300-800 AGM. These mean significantly more power capacity, so it can last twice as long on the water. Not to mention they’re also a lot smaller and lighter than the comparable lead-acid battery, and charge much faster. And you can see the battery state on your phone or via a digital screen. That’s why all reputable electric outboard motor brands, including ePropulsion , use lithium (or even LiFePO4) batteries as their accompanying batteries. Further Reading : Why You Should Choose LiFePO4 Batteries  What size battery do I need for an outboard motor? What amp-hour rating should I get? The electric outboard motor batteries are available in a variety of sizes and power levels. Here is how to calculate the outboard battery sizes in simple steps: Method #1. Start with Amps.Step 1. Get the outboard motor electric consumption in Amps (usually available in the manual). Or calculate with Amps = Watts / Volts. Step 2. Calculate the Amp hour rating of the outboard motor (Ah = Amps x Time). This Ah rating indicates the battery size that will be sufficient for your requirements. For example, if your motor consumes about 60 Amps and you want an outboard motor battery that will last 3 hours, you will need a 180 Ah ( = 60 Amps x 3 hrs) battery. Method #2. Start with Wattage.(Use this method if you know the wattage rating of your outboard motor.) Step 1. Calculate the total watt required for the outboard motor battery (Wh = Watt x Time). Step 2. Calculate the Ah rating with the given voltage (Ah = Wh / Volts). For example, if you own a 1 kW outboard motor ePropulsion Spirit Evo and you want to use it for six hours on a 48V boat system (on a single charge), you will need a 125 Ah battery. Note that the calculation is under full load and max amp draw (meaning you’re running the motor wide open the whole time). In real life, the amp will be much less. That’s to say, you may get away with a smaller battery if you run at part throttle with intermittent use. However, always go for a larger battery if you go with AGM/lead-acid deep cycle batteries. Generally, you don’t want to discharge the battery more than 50% to prevent damage. So half the rated capacity. Alternatively, lithium batteries can be more fully discharged without damage, so you can use more of the rated capacity, which is a big plus for outboard motor batteries. Reading this far, I believe you should be able to decide the best outboard motor battery for your boat. If you are still not sure, here is a simple guide to help you make a quick decision. Essentially, three things to consider: If you are looking for a small outboard motor battery, the weight should be a top priority. You will never want an outboard motor battery to sink your small boat and break your back every time you carry it from your car and to the dock. In that case, the lightweight lithium battery would better fit your needs. Typically, a 12V 100Ah lead acid battery weighs over 60 lbs. Comparatively, a 100Ah LiFePO4 battery weighs only 25 lbs. So you can easily shave about 35 lbs off the weight in your boat. Not to mention its larger usable battery capacity and smaller lighter battery cell. As a Zodiac boat owner reported, his 12V LiFePO4 outboard motor battery lasts 2 times as long as a 120 Ah lead acid that weighs 3 times what the LiFePO4 does. #2. Battery LifeOutboard motor battery life should be a deciding factor in purchase decisions. You need to make sure the outboard motor battery gets enough juice to do the job. So choose an outboard motor battery that comes with a larger battery capacity and longer life cycles. And the lithium battery goes a long way in these two aspects, with at least 80% DoD (depth of charge) and 5 times more charge cycles than lead-acid batteries. However, how long your outboard motor battery can run actually depends on a lot more factors. One of the key factors is outboard power. The best battery for an 25 HP outboard motor is definitely different from the one for 40 HP, since they are running at different watts. For example, if your motor runs at 300W and you use it with a 230Wh LiFePO4 battery, you will get 40 to 50 minutes’ continuous usage out of this battery. Note that throttle power settings also make a great difference in your outboard motor battery life: When moving a boat through water in displacement mode, to go twice as fast you must increase the power about fourfold. That’s to say, if it theoretically takes 200W to go at 2 knots, it would take 800 watts to go at 4 knots. At the same time, going at half throttle may quadruple your range, even though you’ll get there half as fast. Many electric boat owners simply go quite slowly to make the cost and physics add up. Also, you can use a solar panel to help keep your outboard motor battery topped up. Further Reading: Solar Powered Boat Motors: Easiest Way to Set up Your Solar Boat The last step to get the best bang for your buck is to compare costs. And that’s not all about the price tags. Although the lithium outboard motor battery is more expensive, it can last 10+ years if taken care of properly. Actually, it becomes cheaper if you plan to use it for many years. By this I mean that it may cost 2 times more upfront, but it will survive roughly 5 times as many cycles. All in all, a lithium battery would be the best outboard motor battery option nowadays if you want to minimize size and weight and don’t mind a higher upfront cost. Other than that, lead acid is also a reliable technology, proven and improved over hundreds of years. If you have a tight budget, go for a larger lead-acid battery. How to wire an outboard motor to its battery? In fact, it’s easy to hook up your outboard motor battery if you follow the manual. You don’t need to fumble with the outboard motor battery cables to get it plugged in. Basically, you just need to connect the outboard motor and battery with the provided switch cable and communication cable. Also, the control system should be connected to the battery with communication cables. Some small outboards come with an integrated battery, making it easy for the battery wiring. For example, the 3 HP ePropulsion Spirit 1.0 Evo only requires you to place the battery in place (secured by two side slots), and then connect the power cable to the battery.  How to charge an outboard motor battery? Generally speaking, an outboard motor battery needs to be charged with a specialized charger. And the charger decides the charging efficiency. Fast chargers are available for some models, or you can also use two or more chargers in parallel connection to speed up the charging. Does an outboard motor charge the battery itself? Yes, most outboard motors can charge a battery directly while running just like your car’s motor can charge its battery: The engines come with an alternator or generator. When you start the engine up, the engine will charge the starting outboard motor battery until full. If there is an aux battery, it will then switch over and charge the aux battery. More About Outboard Motor Batteries1. does an outboard motor need a battery. Yes, your outboard motor will need a battery to work unless it’s a pull start. 2. Can a lithium battery start an outboard motor?Standard deep-cycle lithium batteries are not designed for starter uses. However, lithium batteries for starting outboard motors are now available, which are specially designed to meet the strict specifications for marine cranking use. In fact, some outboard manufacturers, such as Mercury Marine, encourage users to use qualified lithium batteries to start the engine for optimal performance. 3. Does an outboard motor charge the battery when running?Yes, you can charge a battery from an outboard by burning fuel. For electric outboards, some models (including ePropulsion Navy Evo ) can collect electricity from wind and water and charge themselves via a hydrogeneration function. 4. Can an outboard motor charge a lithium battery?Unfortunately, most outboard motors can not charge a lithium battery directly. You will need a DC/DC charger to make it possible. Other than that, you can invest in an electric outboard motor with hydrogeneration function which allows the motor to charge itself while sailing. Hopefully, this post can help you clear your confusion about outboard motor batteries. If you have other concerns, please leave your question in the comment below and I will get back to you ASAP and add it to the list. Recent Posts ePropulsion Partners with 37th America’s Cup to Supply Sustainable Electric Power for Autonomous Race Marks Why Do Boats Porpoise & How To Stop Your Boat From PorpoisingJoin the discussion cancel reply. Save my name, email, and website in this browser for the next time I comment. Notify me via e-mail if anyone answers my comment. This site uses cookies to personalize your experience and analyze site traffic. By clicking accept or continuing browsing the site, you are agreeing to our use of cookies. See our Privacy Policy here . View the Serial Number  |

IMAGES

VIDEO

COMMENTS

Hiee all, Recently I've been mussing with the idea of getting rid of the transom bracket for the outboard and fabricating a well inside the aft locker and mounting the OB there. It would me centered on the keel line, that 100#s or so would be moved forward inside the boat about 2 feet and the...

building an outboard motor well for a 30-foot sailboat Discussion in ' Outboards ' started by CBTerry, Jun 9, 2017.

How to pick the right outboard motor size for your sailboat? To get the right amount of horsepower needed to efficiently propel a sailboat, divide the displacement of the boat (in lb) by 550. You need approximately 1 HP per 550 lb of displacement or 4 HP per 2200 lb.

Outboard in well | SailNet Community. SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

PAR Yacht Designer/Builder. There are a few engineering details you'll need to work out, but it generally boils down to a enclosed well, with a transom, set at the proper height for the engine (and well under the boat so it doesn't ventilate), a door or plug to seal the hole in the bottom of the boat when not in use and sufficient enough ...

In our boats, we will integrate parts like the motor well, sole and deck in the structure to build a stronger and stiffer boat. In some cases, just like the transom, the motorwell bulkhead is bonded to the hull with more layers than the other bulkheads, see your plans.

Fitting a Sailboat with an Outboard Motor. When the Boat was never Intended. to Have an Outboard Motor. Well, it's the morning of April 15th, 2007 and the sun is shining. Although a mite chilly outside now the temp is supposed to rise into spring-time range in just a few hours. A beautiful morning and I am thoughly "bummed-out."

From the purpose of owning the boat (blue water sailing vs. racing) to the location and impact on maintenance (cold weather vs. tropical weather), an outboard motor is just one of the many elements that will define a sailboat's function and performance.

Here's our roundup of some of the best outboard motors for sailboats, and some help in deciphering what's right for your boat.

Part 1 - Step-by-step description of installing an enclosed tilt-up outboard well on a 28' Pearson Triton sailboat.

The plans call for a conventional transom with the outboard hanging on the stern. However, I want to build an open well for the outboard motor inside the boat. I would much appreciate any suggestions as to how to determine where to put the engine well.

3 enough room for the motor to swing up out of the water. Or not 4 Tiller steering or wheel? 5 Lost buoyancy caused by the hole in the boat. Buy the motor first, build the well to fit it. I made a covered well for our plywood sailboat which is more complicated because there's the rudder hanging off the centerline of the transom to consider.

Motor Well I'm getting old and can only row so far for so long. My two daughters, Samantha and Allie, haven't ever rowed anywhere before. Because of this, we decided to cut a giant hole in the bottom of our beautiful boat so we can install a small outboard. This step of the build was certainly the most nerve-racking. We put so much effort into ensuring the boat was built tight and leak ...

Possibly greater risk of exhaust getting into boat, depending on well design. More difficult to remove rope or line from outboard if prop gets wrapped More drag due to the outboard not being lifted clear of the water. Advantages: Engine head is more protected from elements and salt water. Engine less likely to get swamped Sailingdog Telstar 28

Traditional tip-up motor well The traditional arrangement for adding power by outboard, the tip-up well is a long rectangular box fitted to the bottom of the boat, on which a small horsepower outboard can be hung and into which the prop and shaft can be swung up, safely out of the way when you wish to beach or trailer your boat.

Many outboard-powered boats use brass tube fittings for the motorwell drains. When properly installed and flanged, the fittings function well, but as a boat ages, the relatively thin brass material can corrode, deteriorate and crack, creating an opportunity for water to seep into the transom core. Such was the case with my 21-foot outboard-powered center-console boat built in 1986.

05-23-2012, 06:43 PM. Re: Outboard motor wells. There are a couple good reasons to use a well on an outboard skiff. If none of the situations where they provide advantages apply to you, then you are better off without it. 1) working or fishing boats where gear needs to be handled around the stern.

I am considering cutting out a well in my Cross trimaran for my outboard motor. There is a spot where the framework has been built in to do this but was not finished. I have a 5hp 4 stroke that I use ( I need/want a 9.9hp) and with the outboard bracket I use I still have an issue with cavitation in choppy water. Drives me nuts!!!

I have a John Gardner 19' Surf Dory to which I plan to add an outboard well. I wonder if anyone might be able to advise me on the following points. Maximum horsepower for this application (I am leaning towards a 8hp 4-stroke Yamaha, 83lbs.) Long shaft or short shaft motor/height of outboard well. Depth of prop below dory bottom. Is steering viable using the outboard only, or will I require a ...

20′ Banks Fishing Dory, USCG - Outboard Motor Well. Today I nearly worked all day calculating the outboard motor well. What is left to design and build is the removable tunnel baffle that will start at the bottom "V" of the motor well and come up to the bottom of the rear notch. This will force the prop wash to propel the boat naturally.