Practical Boat Owner

- Digital edition

How to build your own boat stand

- Zoran Glozinic

- May 2, 2024

Zoran Glozinic builds a boat stand for haul-out use

The boat stands are sturdy, but will only be suitable for boats with a shallow keel. Credit: Zoran Glozinic Credit: Zoran Glozinic

Not every boat owner would want to build their own boat stand, but if you decide to do it – for whatever reason – here is one simple way to make them.

This type of stand would work for almost any boat without a deep keel .

It can be scaled up or down to fit your particular boat hull shape/size and it can be easily disassembled for storage, which I think is a big benefit because most stands are really bulky and take up a lot of room when not in use.

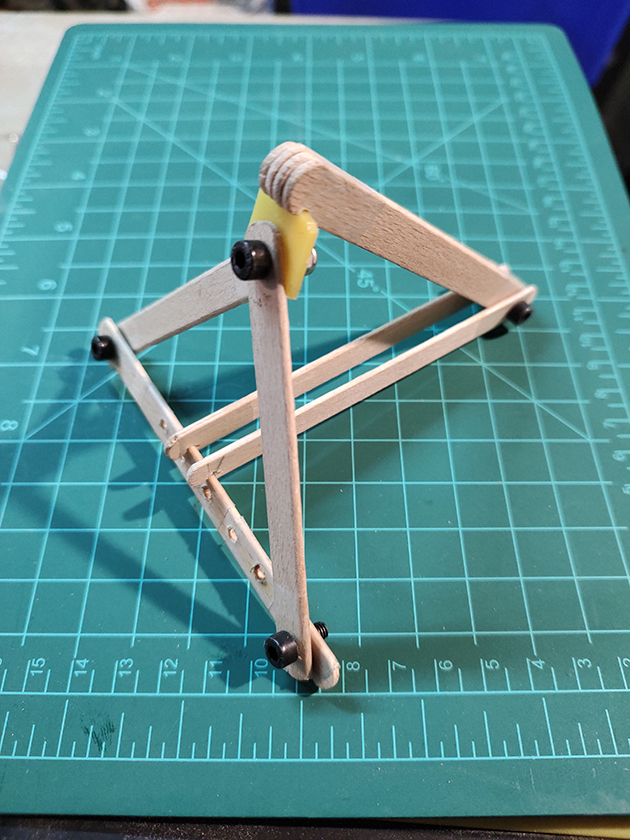

The proof of concept: the model boat stand made from ice cream sticks. Credit: Zoran Glozinic

I recently bought an old wooden motor cruiser and I had to prepare a boat stand before the haul out.

Under ideal circumstances, the best approach would be to take some hull measurements when the boat is on the hard – this way you could design them to fit perfectly.

I was not so lucky so I took some inside hull measurements to help me guess the hull shape but I was not sure how deep the keel was.

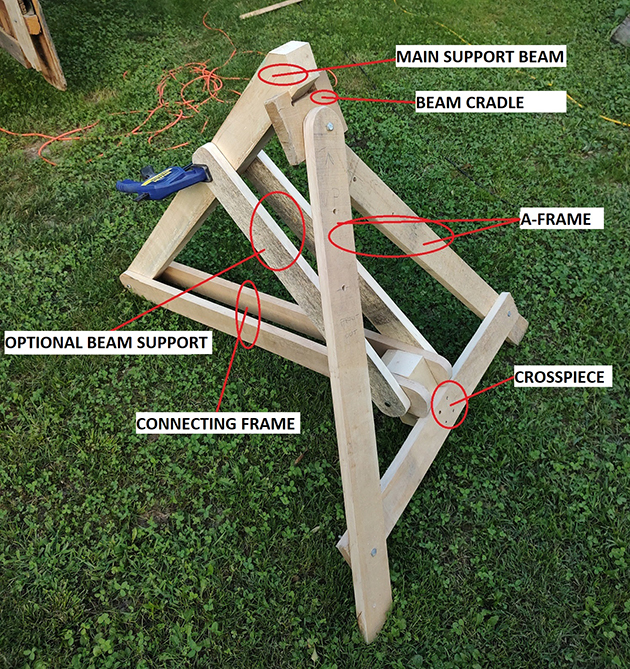

Parts of the boat stand. Credit: Zoran Glozinic

So there was a lot of guessing regarding my design but in the end, I was very satisfied with the result.

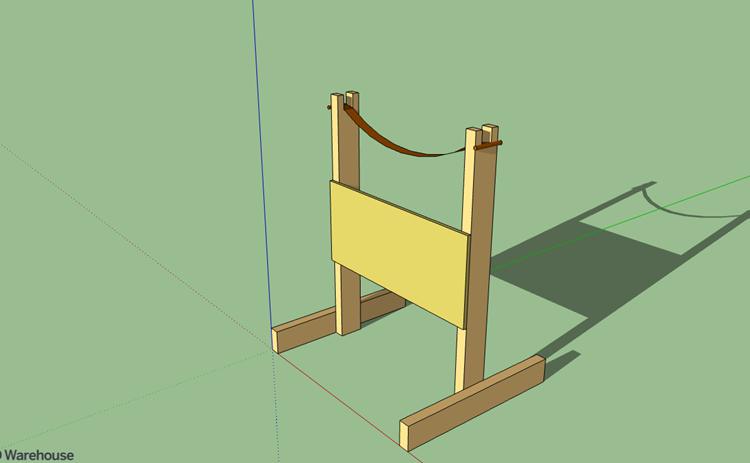

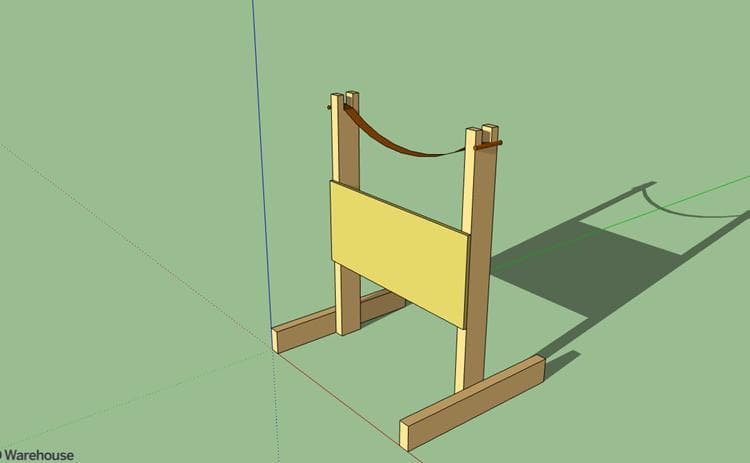

My final decision was to go with an A-frame design, the angle of which could be adjusted.

The resulting change in support height is not ideal but it does help to better support the hull at different hull sections.

Making the main beam cradles. Credit: Zoran Glozinic

The first step I took was to make a small model to make sure my idea would actually work.

I made a model using ice cream lolly sticks and a few small screws: A-frame, main support beam, connecting frame and optional middle support for the main support beam.

The model performed as expected so I was ready to start working on the stand prototype.

Timber choice for your boat stand

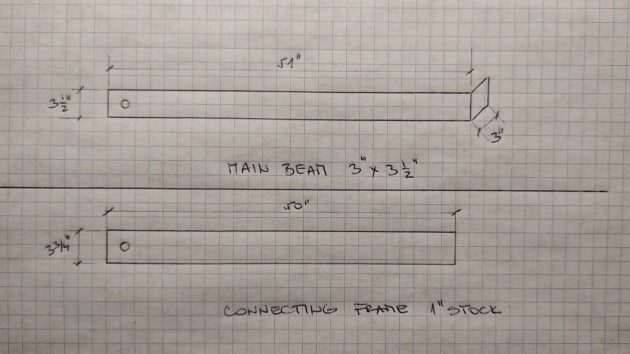

I decided to make all parts of the boat stand using 1in stock timber except for the main support beam which I cut to be about 3in x 3½in in cross-section.

If you’re building much bigger stands, increase the cross-section of the main beam accordingly but most of the other parts can be left at 1in thickness.

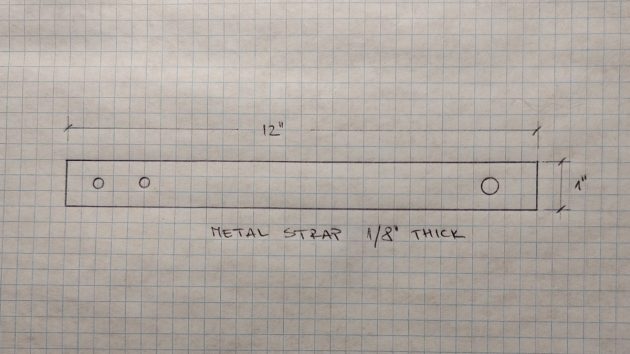

The locking straps were made 1” x 1/8” flat stock steel. Credit: Zoran Glozinic

After cutting all the parts, drill the bolt holes on top of the A-frame legs, on the bottom end of the main support beam and on the both ends of the connecting frame parts.

If you decide to make an optional beam support, drill the holes on one end of each part.

The diameter of the holes will depend on the bolt size(s) you are going to use. I used ⅜in diameter machine bolts I already had at hand.

Zoran built a boat stand prototype. Credit: Zoran Glozinic

If you are building a bigger boat stand, go with at least ½in or bigger bolts.

Make the cross piece and attach the connecting block in the middle of it.

You can use glue as well, but I used wood screws only to attach it to the cross-piece.

The finished boat stand prototype. Credit: Zoran Glozinic

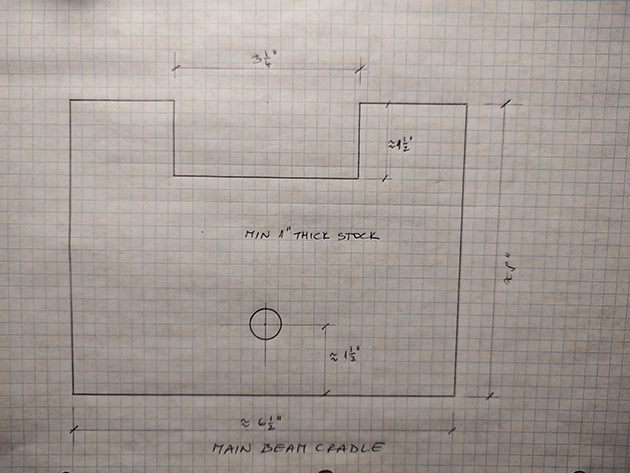

Cut the main beam cradle to size, drill the hole for the A-frame bolt and cut the recess for the main beam.

You can bevel the bottom of the recess at about 30° but this is not critical.

The recess must be deep enough to support the main beam securely to prevent any lateral movement of the main beam.

Portability was an important factor in the design of the boat stands. Credit: Zoran Glozinic

To lock the main beam in place and make sure that it stays there, make a strap from ⅛in mild flat steel.

Around 1in wide strap is enough with a length of 12in.

Drill the hole for the A-frame bolt on one end and two smaller holes for wood screws on the other end.

Assembling the A-frames and main beams/connecting frames. Credit: Zoran Glozinic

I suggest you make parts just for one stand at first and then after assembling it and making sure everything looks OK, you can continue making as many as you might need. I built 10 of them, planning to have five stands on each side of the boat.

In the end, I used only eight because I had some old tyres which I used to support the hull in the middle on each side of the boat.

Since I used a local variety of wood which does not last long unprotected, I applied one coat of wood fence oil on all parts.

Each boat stand is adjustable for ground and hull ange. Credit: Zoran Glozinic

After completing parts for 10 stands and painting them, I removed all passenger seats from my small Fiat and loaded everything for the 400km trip down south to the boat.

Upon arriving and while waiting for the crane to arrive and haul out the boat, I assembled the stands and attached locking straps.

The easiest way is to bend the locking strap in situ – bolt it outside of the A-frame and beam cradle, position the beam inside the cradle recess and then just bend the strap over and onto the main beam top surface using a hammer.

Detail showing how the iron strap holds the main support beam in place. Credit: Zoran Glozinic

Attach it to the main beam with two wood screws – use here at least ¼in screws of 2in length.

I used 3in wood screws to assemble everything – I wasn’t sure how much, if any, modification my stands would need, not being sure if they’d fit the boat shape as I expected.

Continues below…

DIY boat ladder: how to make one on a budget

Zoran Glozinic shares how he made a safe and sturdy DIY boat ladder on a minimal budget

How to make your own cockpit grate: step by step

Zoran Glozinic saves some cash by making a new cockpit grate for his yacht using redundant old wooden kitchen shelves

Bilge pump troubleshooting: getting the float activation switch to work

Zoran Glozinic does a bit of bilge pump troubleshooting to try and work out why the float-activated switch on his…

How to make a budget boat water tank and sink

Fitting out a boat of any size can quickly get pricey, so Zoran Glozinic repurposes some ‘non yachting items’ for…

They mostly did and it was much faster for me to use wood screws to assemble them quickly.

When the work I need to do on the boat is done, I’m planning to replace the screws with bolts so it’ll be easier to assemble and dismantle the stands for storage until the next haul out.

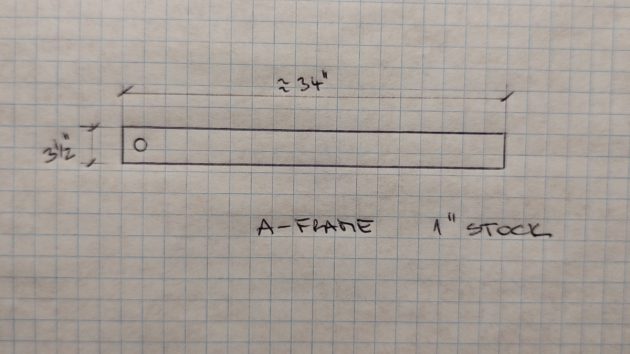

The A-frame component dimensions. Credit: Zoran Glozinic

Once you have all the stands in place, it’s good practice to connect them to each other on each side of the boat and also to connect them from one side to another under the hull.

The dimensions of the main support beam and connecting frame. Credit: Zoran Glozinic

That will minimise the possibility of stands coming loose.

The main beam cradle dimensions. Credit: Zoran Glozinic

Tip: it’s better to make the A-frame parts (legs and cross-piece) longer than you think you might need.

The locking strap dimensions for the boat cradle. Credit: Zoran Glozinic

If the angle of the main beam shows to be too steep, you can always shorten A-frame legs and decrease the main beam angle until you have the desired contact point with the hull.

No other changes are needed. Finer adjustment is done by changing the angle between the A-frame parts.

Enjoyed reading How to build your own boat stand?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

Follow us on Facebook , Instagram, TikTok and Twitter

15 DIY Boat Stand Ideas For Everyone To Try

If you own a boat , you know how important it is to care for it properly. Keeping your boat on a trailer or in the water is an excellent way to ensure that it stays in good shape and is always ready for use. However, keeping your boat out of the water can be difficult if you do not have a place to store your boat. DIY boat stand projects are the best way to ensure your boat is stored safely. These projects allow you to create a customized stand for your boat to store securely outside when not in use.

DIY Boat Stand For Campers

Boat stands are a great way to keep your boat secure and out of the way when not in use. If you have a smaller boat, it can also provide extra space for storage and docking. They are easy to make with just a few tools and materials. Boat stands come in many styles and shapes, but they all have one thing in common: they hold the boat off the ground so that any water drains away from the hull and prevents corrosion. Here are some DIY Boat Stand projects that you can build yourself with some simple tools and materials:

Benefits of DIY Boat Stands projects.

- These DIY Boat Stands can help you save money and time.

- DIY Boat Stands projects are fun, allowing you to customize your boat stand to suit your needs.

- DIY Boat Stands projects allow you to make a stand that will last longer than the store-bought ones.

How To Make A Cheap Boat Stand

Need a cheap, simple, and sturdy boat stand? Here’s a solution that’s both cheap and easy to make. This homemade stand includes a set of wheels attached to the watercraft. The wheels are added while building the frame. The stand is robust and reliable; it can be made in the afternoon with minimal tools and materials. This video tutorial will show you all the steps, so you can quickly build your boat stand that’s sturdy enough to hold the biggest boats. If you love your boat, this inexpensive boat stand can help keep it safe for years.

How To Make A Boat Cradle

If you own a boat, you will need a great stand to store it safely and keep it looking good. I’ve found this simple DIY project to show you how to make a boat cradle. It’s made of two parts that support the weight of the entire boat. This project is simple, but it can be kind of tricky depending on what materials you have. This video tutorial will show you how to make a nice boat cradle that is easily adjustable to fit any size boat.

Boat Stand Quick Build DIY

This guide demonstrates the process of creating a Boat Stand Quick Build DIY. It will help you to make your boat stand, a portable wooden platform that can easily be carried from one place to another. You’ll require a few simple tools, primarily available at home, to start with work. Also, you don’t need special skills or experience; anyone can learn how to make a boat stand in less than an hour. Follow this video tutorial, and you will get the Boat Stand Quickly.

Making A Cheap Boat Stand

This video shows you how to make a cheap boat stand. The creator of the video explains how to purchase the stand and then modify it to fit the design of your needs. It’s not too tricky, and after seeing its effectiveness in this video, it will inspire you to create your own on your driveway. You will be modifying a hoist safety tower for this task, and you can use different boats with it. The key is understanding how this cheap, simple design works before starting the assembly process.

DIY Kayak Stand

Welcome to this kayak stand project. This DIY kayak stand is designed to hold your kayak upright. Its design allows easy access to the hull and body of your boat without having to lay it down on the ground. With no special skills required, you only need a few simple tools, a drill, and some basic woodworking skills to complete this project. The design is excellent, and it's easy to make. This kayak stand stands out while being functional and rustic. The project costs around $10 in materials if you already have the tools.

Portable Kayak Boat Stand DIY

If you are a kayak user, this portable boat stand might be the best for your convenience and ease. A strong and sturdy kayak boat stand can make all the difference in keeping your boat upright on the water or transporting it from one location to another. This easy-to-follow guide tells you how to make a portable boat stand. It’s cheap and requires minimal materials, tools, and time.

DIY 5-Minute Canoe Stand

Make a canoe stand in minutes and keep your boat up. This DIY canoe stand makes it easy to store the boat when not in use and minimizes rusting, a common problem with boats that are left outdoors. Here’s a great project to try when there is nothing else to do on a rainy day. Learn how you can make a boat stand in about five minutes that can be used for an inflatable canoe, kayak, or two-person boat.

DIY Boat Stand Plan

Have you been thinking about a way to keep your boat in the water with minimal effort? Stop daydreaming and make this DIY Boat Stand plan so you can do whatever you want and let it be. The boat-friendly stand is the size of a shelf. It is created from a few materials and will be easy to build since it has been designed with simple instructions. Use this plan to build the perfect boat storage stand in your garage, shed, or basement.

DIY Bait Boat Stand

A simple but effective boat stand is one of the best solutions to keep your bait boat in good condition and from sinking. This DIY bait boat stand works great for fishing or storing live bait while transporting it to your favorite fishing spots and storing it at home. This wonderful idea is created quickly and will save you money by not having to purchase an expensive store-bought product.

Mobile Jon Boat Stand DIY

The Mobile Jon Boat Stand DIY is just the thing for keeping your Jon boat right there, ready to go. Made of high-quality pine and fittings, this lightweight stand will last for years of use. It can support a 12-foot Jon boat or smaller Jons with some additional length. This Jon boat stand is easy to build and essential for keeping your Jon boat safe and clean. The tutorial included all the plans you need to build it to get the exact measurements and construction techniques.

DIY RC Cheap Boat Stand

Are you planning to make a boat stand for your RC boat? If yes, here is the guide that won’t cost you much but will help you build your own boat stand. This video also shows a homemade boat stand with step-by-step instructions and tutorials. This simple yet effective boat stand will allow you to store or work on your RC boat with ease. This is also economical for boat owners because it does not consume too much space and can be made with common materials found at home.

DIY Boat Motor Stand

A motor stand is an important part of any boatyard. Use this DIY motor stand as a workstation or a place to store your boat when it’s not in use. It's easy to make a boat motor stand for any size motor. This boat motor stand is designed to work with small gas motors and electric outboards. You don’t need any special woodworking skills to build one; just a miter saw and some basic tools you probably already have to build.

DIY Cheap Kayak Stand

Do you want to know the inexpensive way to make a kayak stand? This guide will show you how to create one using PVC pipe fittings and cement. You will no longer have to worry about your kayak falling over when your friends come to hang out at the lake. It doesn’t require any special plans or complicated designs. And, it doesn’t take a lot of time to make as well. Even if you are not a DIY expert, this guide will show you how to build your first kayak stand in no time.

Semi DIY Boat Stand

As any kayaker knows, there’s not much more you can ask for than a good solid place to keep your boat upright when you aren’t using it. This semi-DIY boat stand uses two director chairs and some screws to form the stand's frame. Learn how to make a semi-DIY boat stand with director chairs. With the right materials and tools, you can build this stand in just a few hours. The end result will be a flexible and sturdy boat stand that won’t tip over as it’s used.

Fishing Boat Storage Stand

If you have a fishing boat or other watercraft, you will undoubtedly understand how difficult it is to store them. Ideally, a cover is best, but not everyone has the ability to store their boats indoors. This simple DIY storage stand is the answer. This DIY fishing boat storage stand is a great way to store your fishing kayak or canoe. Here is an easy-to-follow guide to getting started. First and foremost, check the cut and tool list to learn more about the project. Good luck!

Sharing is caring!

5 Best DIY Boat Stand and Cradle Ideas [Video]

Let’s face it, factory-built boat stands can be very expensive. Because of this, DIY solutions are becoming more and more popular.

Based on our research, the best DIY boat stand and cradle ideas are as follows:

- DIY wooden boat stand

- DIY metal boat stand

- DIY wooden boat cradle

- DIY metal boat cradle

- Small DIY boat dolly

If you want to drill into the details, keep reading.

We at PowerSportsGuide have compiled all you need to know under one roof!

5 Best DIY Boat Stand and Cradle Ideas

1. diy wooden boat stand ideas.

There’s no question that one of the most popular materials for constructing boat stands is lumber.

It’s easy to work with and relatively cheap, and it can often be found around the house.

There are two main types of DIY wooden boat stands. The simpler, more universal units are similar to metal triangle boat stands with plywood pads (a.k.a. poppets), which can be placed and aligned separately.

The other solution is to build a complete frame with four regular plywood pads or two supporting “braces.” The latter design offers greater safety and better support for the boat but it’s also harder to build.

When it comes to building these types of wooden boat stands, you should carefully shape the braces so they follow the outer line of the hull.

How can you copy the exact shape of the hull?

Best practice is to make a template using cardboard strips and some hot glue. This cardboard template will help you shape the supporting braces much easier.

If you don’t want to design your homemade boat stand from scratch, you can also find many plans for wooden boat stands online or in wooden boat magazines.

Here’s a simple example of a wooden boat stand:

2. DIY Metal Boat Stand Ideas

It’s safe to say that the most common boat stand design is metal triangles featuring plywood pads.

Used triangle boat stands are sold everywhere, so building one is usually not worth the hassle. You can find plenty of them for sale on Craigslist, Facebook, or even locally in boat yards.

But if you are determined to build one no matter what, you can build a sturdy DIY metal boat stand from steel profiles:

However, standard triangle-style stands can also be built from scrap materials:

If you don’t want to build it from scratch, you can also turn standard car jack stands or Acrow Props into DIY boat stands with a little modification:

3. DIY Wooden Boat Cradle

The main drawback of standard boat stands is that they don’t allow the boat to move.

This is where DIY boat cradles come into play.

In this video, a wooden boat cradle is built by using car dollies as a base (a very solid and cost-effective solution):

4. DIY Metal Boat Cradle

DIY boat cradles can also be built of metal, just make sure to use wooden bunks to avoid hull damage:

5. Small Wooden Boat Dolly

If you want to transport a smaller row boat or a dinghy to the water, you will only need a simple, 2-wheeled boat dolly.

It can be built of lumber, metal, PVC plumbing pipes, or a mix of materials. Just build the frame and add a pair of utility wheels to it.

It’s as easy as it sounds!

There are many ways to build a great DIY boat stand or cradle. A well-designed and carefully built unit can be as rigid and durable as its factory-built brothers.

In most cases, these structures are made of metal or wood, but smaller row boats can even be stored on PVC pipe stands.

What not to use as a boat stand?

Contrary to popular belief, using cinder blocks as a boat stand is definitely not recommended!

Since these blocks are not designed for point loads, they can get smashed under the weight of a boat.

Using stacked wooden blocks, vehicle tires, or Styrofoam blocks are not good ideas either.

These solutions can’t provide safe support for your boat, which can be dangerous in many ways. Boats are large, heavy, and expensive, so gambling with them is simply not worth the risk.

This is why you should build a solid DIY boat stand or invest in a high-quality factory unit!

Related Articles

Based on our research, the 7 best DIY boat stabilizer (a.k.a. DIY boat collar) ideas…

Based on our research, the best materials and bases for building a DIY outboard stand…

Recent Content

How Much is a Honda Outboard Motor? [Price List]

The prices of Honda outboard motors start at $1,000 and climb up to a whopping $27,000. To be more precise, average prices within each category are as follows...

How Much HP does a Yamaha Outboard Have? [Chart]

As a rule of thumb, Yamaha outboard motors house 2.5-450 HP engines depending on the model. To be more precise, the engine power in each main class is as...

- 2024 BOAT BUYERS GUIDE

- Email Newsletters

- Boat of the Year

- 2024 Freshwater Boat and Gear Buyers Guide

- 2024 Boat Buyers Guide

- 2024 Water Sports Boat Buyers Guide

- 2024 Pontoon Boat Buyers Guide

- Cruising Boats

- Pontoon Boats

- Fishing Boats

- Personal Watercraft

- Water Sports

- Boat Walkthroughs

- What To Look For

- Watersports Favorites Spring 2022

- Boating Lab

- Boating Safety

- Ultimate Boating Giveaway

“Blocking” Your Boat

- By Joe Friedman

- Updated: September 9, 2011

“Blocking” Your Boat

How your boat is “blocked” once it’s off the Travelift or the trailer is critical. While a boat can be blocked properly on cement blocks, jack stands (aka “boat stands” or “poppets”) are the pro’s choice. Some boat manufacturers recommend positioning for blocks and jack stands, so check the owner’s manual or with the builder. Generally, keel blocks should be positioned under internal bulkheads to avoid stressing the boat. Improper blocking can lead to gelcoat stress cracks, damaged stringers, misaligned engines and other problems. Check for proper blocking under your boat or that new one you’re considering.

Be Well Grounded The ground should be solid and reasonably flat. Regardless of the surface, place the stands on plywood bases to spread the load and prevent the stands from settling. Even asphalt will give way, especially if it gets hot.

Keel First The keel takes all the weight, so it gets supported first. You can use concrete blocks with wood on top, but special poppets called keel stands with threaded rods are more convenient. Keel stand pads screw up flat. A minimum of two stands will enable you to level the boat fore and aft. Use one stand for every 10 feet of length along the keel.

Balancing Act Position one adjustable stand every eight feet with a minimum amount of threaded rod exposed. The base should be parallel to the waterline and as far out from the keel as possible, generally tucking the pad into the chine. Thread the pads up, one side at a time, and finish when they are secure against the hull and the boat is level abeam.

- More: diy projects , How-To , winterizing

More How To

Grady-White Pulls off Its Largest Raft-up Ever in Vieques, Puerto Rico

Installing Retractable Transom Straps

How to Choose a Trailer Winch

Best Non Skid Boat Deck Paint

Boat Test: 2024 Fjord 39 XP

2025 Alumacraft Competitor 205X

2025 Alumacraft Trophy 185X

2024 Alumacraft Timeline: Two Groups of Boaters x One Day Out on the Water

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Many products featured on this site were editorially chosen. Boating may receive financial compensation for products purchased through this site.

Copyright © 2024 Boating Firecrown . All rights reserved. Reproduction in whole or in part without permission is prohibited.

15 DIY Boat Stand Ideas to Safely Display and Maintain Your Boats

If you own a boat, you understand the importance of proper care and storage. While keeping your boat on a trailer or in the water is ideal, DIY boat stand projects offer a customized solution for safely storing your boat outside when not in use.

This article explores the benefits of DIY boat stand projects and how they help keep your boat in good shape and ready for use. With a few simple steps, you can create a stand tailored to your boat’s needs for secure storage.

How To Make A Boat Cradle

A sturdy stand is essential to safely store and maintain your boat’s appearance. This DIY project involves creating a boat cradle that supports the entire boat’s weight. While the project is relatively simple, available materials may make it more challenging.

The tutorial includes instructions for easy adjustments to accommodate boats of any size. Follow the steps outlined in the video tutorial to create a functional and aesthetically pleasing boat cradle.

Portable Kayak Boat Stand DIY

This guide provides step-by-step instructions for making a portable boat stand. It’s a cost-effective project requiring minimal materials, tools, and time.

DIY 5-Minute Canoe Stand

Creating a canoe stand is quick and efficient, keeping your boat properly stored and preventing rusting. This DIY project provides an easy solution for storing inflatable canoes, kayaks, or two-person boats. It’s an ideal rainy day project when you’re looking for something productive to do.

DIY Cheap Kayak Stand

Here’s an inexpensive way to make a kayak stand using PVC pipe fittings and cement. This guide walks you through creating a sturdy stand that prevents your kayak from tipping over, perfect for lake outings with friends.

It’s designed to be straightforward without special plans or complex designs, and it won’t take much time to assemble. Even if you’re new to DIY projects, this guide will help you build your first kayak stand quickly and easily.

Semi DIY Boat Stand

Form the frame by attaching the director chairs together with screws. The result is a reliable boat stand that keeps your boat upright when not in use. Click the link to get started on building your own semi-DIY boat stand.

DIY RC Cheap Boat Stand

For an affordable way to make a boat stand for your RC boat, follow this simple guide to build your own without breaking the bank.

The video provides step-by-step instructions to make a homemade boat stand. This stand is easy to build and effective for storing or working on your RC boat.

It is economical for boat owners, made with common materials found at home, and does not consume much space.

Making A Cheap Boat Stand

For an affordable way to store your boat, making a cheap boat stand is a great option. In this video, you’ll learn how to modify a hoist safety tower to fit your boat’s design. The process is simple and easy to follow, allowing you to create your own boat stand quickly.

The key to success is understanding the design before starting assembly. With this knowledge, you can confidently modify the stand to fit your boat’s unique needs and save money by making your own instead of purchasing an expensive one.

DIY Boat Stand Plan

For a simple and efficient way to store your boat, try this DIY Boat Stand plan. With easy-to-follow instructions and a few basic materials, you can create a stand that is the perfect size for your needs.

Whether you want to store your boat in your garage, shed, or basement, this plan has you covered. With minimal effort, you can create a stand that keeps your boat safe and secure, allowing you to focus on enjoying your time on the water. Click the link to get started!

How To Make A Cheap Boat Stand

Building a boat stand using a modified hoist safety tower is practical. Watching the video and seeing how the creator adapts and enhances the stand’s design can inspire you to customize your own version.

Understanding the simplicity and effectiveness of this DIY project can motivate you to tackle it in your driveway, accommodating various types of boats.

DIY Bait Boat Stand

A simple yet effective boat stand maintains your bait boat in good condition and prevents sinking. This DIY bait boat stand is particularly useful for fishing, allowing you to store live bait, transport it to fishing locations, and keep it stored at home.

It’s a practical and cost-saving idea that can be quickly created, sparing you from buying a more expensive commercial product.

Mobile Jon Boat Stand DIY

The Mobile Jon Boat Stand DIY is a lightweight and durable stand made of high-quality pine and fittings, perfect for keeping your Jon boat safe and clean. This stand is easy to build, and the tutorial includes all the necessary plans for exact measurements and construction techniques.

The Mobile Jon Boat Stand DIY can support a 12-foot Jon boat or smaller boats with additional length. With this stand, your Jon boat is always ready to go. It’s an essential tool for any Jon boat owner who wants to keep their boat in good condition.

Boat Stand Quick Build DIY

Creating a Boat Stand Quick Build DIY is a simple process requiring only a few basic tools found at home. With no special skills or experience needed, anyone can make a portable wooden platform to hold their boat.

By following the step-by-step video tutorial, you can build your own boat stand quickly and easily in less than an hour. The Boat Stand Quick Build DIY is a great solution for those who need a portable and sturdy platform for their boat.

DIY Kayak Stand

If you’re looking for a simple and inexpensive way to store your kayak, this DIY kayak stand is a great option. With a design that allows easy access to the hull and body of your boat, this stand keeps your kayak upright and off the ground.

You don’t need any special skills to build it, just a few basic tools and some woodworking knowledge. The stand is both functional and rustic, and costs around $10 in materials if you already have the tools. Follow the instructions provided in the link below to build your own kayak stand.

DIY Boat Motor Stand

A motor stand is crucial for any boatyard, serving as a workstation or storage space when your boat is not in use. This DIY boat motor stand is versatile and suitable for motors of various sizes, whether small gas engines or electric outboards.

You can easily build it without requiring advanced woodworking skills—just basic tools like a miter saw and common workshop tools will suffice.

Maintaining your boat requires a sturdy and reliable boat stand. DIY boat stands are cost-effective and customizable for boat owners. Using materials such as PVC pipes, wood, or metal, you can create a stand that fits your boat’s specific needs.

Consider factors like weight capacity, stability, and adjustability when building your stand. With proper construction and maintenance, DIY boat stands provide a safe and effective solution for your boat storage needs.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

The $tingy Sailor

Diy trailerable sailboat restoration and improvement without throwing your budget overboard.

Turn Scrap Lumber into an Outboard Motor Stand

My most essential tool for working on my outboard motor is its stand. Without it, maintaining my 80+ pound, 8 HP Yamaha 4-stroke would be like a wrestling match.

Before I continue, a bit of legal housekeeping. This post contains affiliate links. That means I receive a small commission if you make a purchase using those links. Those commissions help to pay the costs associated with running this site so that it stays free for everyone to enjoy. For a complete explanation of why I’m telling you this and how you can support this blog without paying more, please read my full disclosure .

You don’t want to store an outboard motor lying on a floor or workbench in your garage when it isn’t on the boat, especially all winter. You want it to be easy to work on, to move around, and to load and unload either from your tow vehicle or the mount on your sailboat. A motor stand, especially one on casters, makes maintenance and storage a breeze.

You can buy a manufactured stand, like this one from Garelick , but if you have a few spare 2x4s and some deck screws, you can make one for next to nothing. All you need is a good set of plans.

I found these these excellent plans that saved me hours of designing a stand of my own. You can download the PDF file, print it out and build it in a couple of hours. The drawings are clear and accurate. I like that the stand has a convenient place on the front of it to hold a gas tank. That makes moving the motor outdoors for test running and flushing easy-peasy.

After using this stand for more than 7 years, it’s as strong as ever and it’s saved my back many times. This project is a no-brainer and one you’ll be glad you did.

Would you like to know when I publish more posts like this? Enter your email address below to subscribe to this blog and receive notifications of new posts by email. You will also receive occasional newsletters with exclusive info and deals only for subscribers and the password to the Downloads page. It’s free and you can unsubscribe at any time but almost nobody does!

blog_subscription_form

Share this:

24 thoughts on “ turn scrap lumber into an outboard motor stand ”.

This post is perfectly timed. I was considering building my own stand recently and now you’re right…Don’t have to find plans. Thanks!

I made a moveable one for my 10 hp Honda from an old bag trolley. I can wheel it around. We sometimes have these trolleys on sale at the autoshop for $25. The rest is scrap wood. Our driveway gravel and not suitable for casters. can send photo….

Yes sir, that’d be great!

I think Peter is talking about making one from an abandoned shopping cart, like here .

Here is my Honda hand cart. It is a bit rough and has been out in the rain for a couple of years as the boat is elsewhere and I’ve done the servicing on the boat. It worked well enough for me. You can see that I have put a bar across to give it sideways stability. An improvement would be to extend the tray out so that the foot of the motor rests on it. I used to rest the foot on a block to stop it tilting forward on my gravel and sand block. I used to wheel it up to the ute, drag the motor over the tailgate until it tipped then with the motor upright it was a reasonable lift to get it on the trolley. Then I could wheel it wherever.

That’s not stingy that’s thrifty!

Thanks for the inspiration. I built a scaled-down version (16″ wide) today for my 5HP Honda. All scrap lumber, but I bought casters and screws, so not quite free.

Good on ya, stingy Dave!

What do you think weight limit would be? I have a very old (70’s) 40 hp Mercury.

I think this stand would hold your motor if it’s tall enough. Besides deck screws, I would also also apply construction adhesive to all the joints and if you’re going to use casters, get larger and heavier duty ones than shown here.

These work great! I made mine from some scrap 2 x 4’s laying around so the only money spent went for two castoring wheels and two fixed wheels. I plan on making another one for my other outboard.

Do you have a better link to the PDF with the plans? The link in the blog doesn’t point to them anymore.

Cheers Noah

Sorry, I do not.

Built one of these for my Mercury 4.5. Works great!

Hello. I am unable to locate the plans. I found the PDF link but when clicked it says the file is empty. You don’t have the ability to add a fresh link for those plans do you?

The link should work now.

Thanks for reposting. I built a couple of them two summers ago and they are the handiest stands I have in my shop. They work great! I use them for my Mercury 4.5 and 9.9 engines.

Thanks, Ben

Thanks for the outboard motor stand resource. My son is going make this in his high school shop class.

I just finished building this. It’s very solid, but unfortunately it’s too short for a long shaft motor (Merc 9.9). I had to replace the upper 2×6 with a 2×12 to get it high enough. I’ll probably have to extend and reinforce the upper supports since the top 5” of the 2×12 is unsupported, and there’s a lot of torque on it from the mounting brackets.

That is my situation exactly (9.9 long shaft). What changes did you make to support the upper port?

Thanks for hosting these plans, and to D. Hayes Jr, wherever he is. The double on the uprights seems like overkill for most C22 auxiliaries. I skipped the casters for a stable platform for transporting in the bed of the truck.

what is the reason for the 8 deg cut at the bottom? Do you think I can build this without those and have the main supports be 90 deg to ground ?

The angle makes it a little easier to mount the motor and it gives you a little more room to work around the lower unit but yes, you could make it a right angle and it should still work.

Your post is right on. I built a stand out of scrap wood for outside to run, change the oil and general maintenance. I also added a motor mount inside the garage for storing my outboard during the winter.

Leave a comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

How to put a Boat on Stands | Quick and Easy

Boating in the summer is truly an unprecedented and enjoyable experience that is usually not easy to express in words. Most of the pleasurable things in the world may seem trivial to someone who has gained this experience once, I must say.

But this delightful summer trip no longer lasts into winter. Then it is necessary to lift the boat to a better place and store it well for the next year.

For those who have no previous experience with this subject it can seem painful and quite difficult. But believe me, it’s not as difficult as you think. This is a very simple and easy thing to do if you follow a number of rules.

Let’s see how to get a boat from the trailer to the stand very easily.

What Things are Needed to Set it Up?

You will need several materials to put a boat from the trailer to the stand. Two of these materials are in your collection that may no longer need to be purchased. But the rest of the accessories you must buy.

Of course, how much to buy depends a lot on the size, weight, design of your boat.

Below are the things you need to make your boat stand up well.

Good quality motorboat stand

- Keel Stands (optional)

- Stern Stand (depends on boat size)

- Good quality blocks

Jack Stands

- Wood (Optional)

No matter what the size of your boat, you must need a good quality motor boat stand .

How many boat stands will be needed depends on your boat. If it is small, two stands are enough. Again, if the size of the boat is large, it may take six to eight.

Keel Stands and Stern Stands

The keel stand is usually used in the case of a large boat. These stands tend to be a little curved for use on the bottom of the boat.

In the case of stern stand, a slightly larger or longer type of iron reinforced bar is used. It is usually used on the front of the boat.

These stands are very optional. If you do not want to use, you need to use blocks. However, we strongly recommend that you use them.

Good Quality Blocks and Woods

Such blocks or timbers carry almost all the weight of the boat. And so in this case it is essential to use good quality blocks and wood.

Of course, if you don’t want to, you can continue working without any of these.

You can compare this stand to a lot of car jacks. It is used to lift your boat and keep it afloat.

Hopefully you’ve got a rough idea of what kind of materials you’ll need to put your boat on the stand.

The Process of Landing on the Stand from the Boat Trailer

So far we know about the different materials. Now let’s go to the original part of this article.

Every step in this part has to be followed well. There is no way to separate one part from another, then the whole plan will be ruined.

- First the boat has to be taken to a dry and hard place with its trailer. Make sure that the soil where you put it is not soft under any circumstances.

- Now slowly lift it from the two sides of the back of the boat with two motor boat stands. In this case, two people must turn the handle and lift up together, otherwise the boat may be tilted.

- When installing the stand, the bottom must be well supported with wood, otherwise it may tilt to one side over time.

- Now stick the keel stand at the very bottom of the boat from the back. You can also do this with wood if you want. But these stands are best for good results.

- Now you have to turn the handle along the middle of the boat with a jack stand or jack and hold each other. Then move the trailer forward a bit until its axle touches the jack.

- Now another jack should be placed behind the axle to lift the boat up and the front jack of the axle should be gently lifted. It should be well supported with blocks and boat stands so that it does not tilt or move under any circumstances.

- If the size of the boat is a little small or medium type, you can use the stern stand to support the boat from the front.

- Now if the boat is in perfect balance on wood, keel stand or block, then slowly pull the trailer from the front. This is pretty much the last step in getting the boat out of the trailer.

Hopefully you have a fair idea of how to do it. Also, I hope you don’t think it’s as difficult as you thought at first.

Things that Shouldn’t be Done

- When you turn the handle of two jacks and lift the boat, you must lift the boat together. Under no circumstances should you lift it to one side only.

- Do not move the trailer forward in any way until the boat support from the rear is very well ensured.

- Lay the blocks or woods on the bottom of the keel very well and firmly so that there is no gap between them. Check it out once more before removing the trailer.

Related: 9 Outstanding Reasons to own a Boat

Final Thought

If you follow each of the steps above, I’m sure you’ll be able to get your boat right from the trailer to the stand.

Related Posts

8 Major Difference Between Boat And Ship

How much does a Boat Motor Cost

Leave a comment cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

How to Build a Portable Outboard Motor Stand

Posted by Michael Maddox on Apr 15th 2014

When I recently bought an outboard motor, I needed a stand to keep it on while I finish building my Glen-L boat. I found a few good tutorials online for building your own stand. However, I wanted my stand to have the same 12 degree transom angle that is common to many Glen-L outboard boat designs. Borrowing ideas from some of the better tutorials I found, I made some basic modifications and came up with this.

For lumber, tools and materials, I used: (4) 2x4x8 boards, (1) 2x8x8 board, (2) regular casters, (2) locking casters, a circular mitre saw, a circular saw, a cordless drill, misc. bar clamps, 3” wood screws, and (16) 1” lag screws.

Getting started on the base

(When attaching parts during construction, pre-drill the holes before driving the screws.)

Start by cutting four pieces of 2x4: two pieces that are 36” long, and two pieces that are 24” long. The 36” pieces will form the base of the motor stand.

Take the two 36” base pieces, and decide which will be the forward ends and aft ends. Measure and mark a line 16” aft of the forward ends. This will mark the location for the upright supports. (*Note: for lighter motors, such as my 8hp rated at 81lbs, you can also mark this line at 18.”)

Measure and mark a line 16 inches aft of the forward end. 18 inches is optional for lighter motors.

Attach one 24” piece so that it connects the two 36” base pieces at the forward end. This will form part of the “shelf” for holding the gas tank, etc. You may find it useful to only use one screw per end, so that you can easily square up the assembly when you add more parts later. Set the second 24” piece aside for the moment.

Fasten one of the 24-inch pieces to the forward end of the 36-inch base pieces. This will form the forward end of the shelf.

Adding the support blocks

Set your mitre saw to cut at a 12 degree angle.

Cut two 4” pieces of 2x4 so that one end has the 12 degree cut, and the other end is left square. Make sure both pieces are equally sized. Trim the square end if necessary. These pieces will be blocks that will support the upright sections of the motor support.

Cut a 4-inch support block using 12 degree angular cut.

Place one of these 4” support blocks upright on one of the 36” base pieces. Align it on the forward side of the line you marked earlier. Using this piece as a guide, mark another line across the 36” base piece on the forward side of the upright block. Repeat on the other 36” base piece. You should now have two lines marked on each base piece.

Use the support block as a guide to draw a second line, forward of the first one.

Lay the 4” support block down on the 36” base piece, so that the short side of the block is in contact with the base. Align the angled end of the block onto the second line you marked. The angled end of the block should now be facing the aft end of the base. Fasten the 4” support block to the 36” base. Repeat on the other 36” base piece.

Attach the support block so that its angled end faces aft.

Fit the second 24” piece you cut earlier against the squared ends of the 4” support blocks. Make sure the assembly is squared, and fasten this 24” piece to the 36” base pieces as shown. This will form the aft end of the shelf for the gas tank, etc. If you only used 1 screw per side of the original cross-piece, go ahead & add more screws to prevent any flexing or movement of the base.

Attach the 2nd 24-inch piece to the base assembly. This will form the aft end of the shelf.

Building the upright supports

With your mitre saw set to cut at a 12 degree angle, measure and cut to two 32” lengths of 2x4, so that one end has the angled cut, and the other end remains squared. These will be the upright pieces of the motor support.

Measure and cut a 24” piece of 2x8. This will be the motor board. Both ends should be squared.

Align the two 32” upright supports on the floor, so that their angled ends are in alignment. The long sides should be facing upward. Place the 2x8 motor board across the uprights, and align it with the top, or squared ends. Using the 2x8 motor board as a guide, draw a line across the 32” upright supports.

Use the motor board as a guide to draw a line across both upright supports.

Place the base assembly on its side, on the floor. Fit the angled end of one of the 32” upright supports into position against the 36” base and the angled cut of the 4” block. Using the block as a guide, mark a line across the 32” upright support. Repeat on the other 32” upright support.

Use the support block as a guide to draw a line across each upright.

You should now have two lines marked on each upright support. Measure the distance between these two lines. It should be approximately 23.5”.

Measure the distance between both lines on the upright supports.

With your mitre saw set to cut at 12 degrees, cut two more pieces of 2x4 to the length you just measured. One end should have the angled cut. The other end should remain squared. Make certain that the short side of this piece equals your measured distance, (approximately 23.5”). These pieces will reinforce the upright supports.

Align each 23.5” reinforcing piece onto each 32” upright support. The short side of the reinforcing piece should fit between the two lines marked on the long side of the upright support. Fasten into place.

Place and attach the reinforcing pieces onto the upright supports.

Fasten the motor board into position on the upright supports, making sure the assembly is squared.

Attach the motor board.

Adding the casters

Turn the base assembly upside-down on the floor. Place, mark and attach the casters into position as shown, using the 1” lag screws.

Place and attach the casters.

Attaching the motor support assembly to the base

Take both the motor support assembly and the base assembly, and place them on their sides on the floor. Fit them together, and clamp them firmly into position. Fasten them together by driving two 3” wood screws upward through the base & into the bottom of the upright supports. Drive a third 3” wood screw through the back of the upright support & into the 4” support block. Carefully turn the assembly over, and repeat these steps on the other side.

Attach the motor board assembly to the base.

Fastening the motor board assembly to the base assembly.

With the assembly still on its side, place a small scrap of 2x4 underneath the forward part of the stand. Place a longer section of 2x4 underneath the aft end of the stand, and position it between the base and the motor board. This will be the aft support of the motor board assembly, so arrange it for maximum support of the motor board. Using the base and the upright support as guides, mark the lines on this piece of 2x4. Cut to these lines. This will be the motor board support.

Place and mark the cut lines for the motor board support.

Using the motor board support as a template, mark and cut an identical piece from another section of 2x4. Fit each motor board support into position and fasten into place with 3” wood screws as shown.

Use the motor board support as a template for making a 2nd one.

Attaching the motor board support to the back of the motor board assembly.

Attaching the motor board support to the base assembly.

Stand back and admire your work. You’re done!

Completed outboard motor stand.

- #Boat Builder

- #Boat Builders

- #Boat Building

- #Boatbuilder

- #Boatbuilders

- #Build A Boat

- #Building A Boat

- #Dream Boat

- #outboard motor bracket

- #outboard motor stand

DIY Sailboat Project

Monday, may 1, 2017, build model boat stand.

The hull truth boating and fishing forum about building stands from 4x4 and 2x4's. the boat is a 20 the winter as it is a 22' walk-thru model. I have two projects on the building board right now. a pirate ship and a 30's cup racer and they both need display stands. any good looking ideas?. There are lots of ways to build them, if the boat stand is for a hydroplane model, the trimming is usually easier since the hydro has a flat bottom..

I have a question regarding stands for model boats i have looked every where. do you know anyone selling stands? there are many types of stands for model. There comes a time in the process of building any model boat when you need a stand. very few hulls are designed to sit solidly and level on a flat surface. Make your own boat stand in 6 easy steps. this stand works well for just about any boat up to 22 feet in lenght. modify and build as necessary..

Related Posts by Categories

Posted by bari at 11:14 PM

Labels: Boat Plans

0 comments:

Post a Comment

- ► April ( 51 )

- ► March ( 79 )

- ► February ( 73 )

- ► January ( 71 )

- ► December ( 79 )

- ► November ( 70 )

- ► October ( 68 )

- ► September ( 201 )

- ► August ( 204 )

- ► July ( 207 )

- ► June ( 106 )

- ► April ( 15 )

- ► March ( 76 )

- ► February ( 100 )

- ► January ( 113 )

- ► December ( 177 )

- ► November ( 125 )

- ► October ( 119 )

- ► September ( 244 )

- ► August ( 157 )

- ► July ( 165 )

- ► June ( 147 )

- harris boat works canada

- speed boat plans and kits

- build model wooden ship

- build your own boat kits

- arch davis design boat plans

- build your own layout boat

- plywood dory boat plans

- wooden race boat plans

- duck boat plans plywood

- aluminum offshore boat plans

- fishing boat plans wooden

- wooden boat plans whitehall

- free plans boat building stitch and glue

- simple aluminum boat plans

- flat rat boat plans

- build rc boat plans

- kayak building kits uk

- how to build a model boat out of cardboard

- rc boat scratch built

- boat planter outdoor

- harris boats fort wayne in

- dave harris boat for sale

- how to make a model jet boat

- boat plans free canoe

- sailboat design software

- small boat building forum

- isle of harris boat hire

- wooden catamaran boat plans

- 16 ft flat bottom boat plans

- build your own houseboat

- sailboat building business

- free wooden boat plans uk

- josh harris boat

- aluminum jon boat plans free

- model boat builders mauritius

- build your own rc boat trailer

- build your own model sailing boat

- centurion rc boat build

- acorn skiff boat plans

- build your own boat workshop

- outboard boat plans free

- boat shaped window planter

- modern plywood boat plans

- lightweight plywood boat plans

- plywood layout boat plans

- scratch build model ship plans

- how to build a model boat free plans

- whitehall rowing boat plans

- wooden ski boat plans australia

- fiberglass boat building step by step

- build your own boat garage

- build a rc boat kit

- offshore plywood boat plans

- wooden model ship building kits for beginners

- harris lake boat ramps

- building model lobster boat

- harris lake boat storage

- one plywood boat plans

- model boat plans balsa wood

- hydroplane boat plans for sale

- simple boat plans free

- building flat bottom boat with 1/4 in plywood

- panga boat plans free

- model boat building books

- catamaran boat building

- carolina skiff work boat

- fibreglass boat building forum

- building model ships from scratch kent porter

- small flat bottom boat plans

- wood rc sailboat plans

- flat bottomed scow boat plans

- build fe rc boat

- build your own boat bimini

- build your own pontoon boat furniture

- rc boat hull construction

- build your own u boat magazine

- flat boat building

- making model boat stanchions

- 518 boat plans free download

- layout boat plans free

- plywood rowboat plans

- pooduck skiff boat plans

- rc boat how to build

- boat planters filey

- flat bottom fishing boat plans

- harris st kilda boat trips

- how to make your own model ship display case

- how to build model boat

- model boat building ideas

- how to build a boat motor cover

- micro skiff boat plans

- how to build a model jet boat

- catamaran fishing boat plans

- build your own boat interior

- glen l boat plans free

- building wooden model ships from scratch

- harrac boat

- how to make model boats out of wood

- ► April ( 90 )

- ► March ( 51 )

- ► February ( 71 )

- ► January ( 84 )

- ► December ( 88 )

- ► November ( 147 )

- ► October ( 106 )

- ► September ( 56 )

- ► August ( 65 )

- ► July ( 63 )

- ► June ( 60 )

- ► May ( 188 )

- ► April ( 191 )

- ► March ( 129 )

- ► June ( 68 )

- ► May ( 66 )

- ► April ( 72 )

- ► February ( 4 )

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Made a simple Outboard Motor Stand

- Thread starter CrispyCringle

- Start date Jan 14, 2017

- Hunter Owner Forums

- Smaller Boats

CrispyCringle

Regular Guy

CC, I like that, need one too. Going to make one like such. There is not much extra room in my garage, that slim design is just fitting. Thanks for posting your idea. Hart

Michael Davis

Made something similar for mine. Just a little wider so I could put a 5 gal pail of water there to flush the engine after a season in saltwater.

Nice job. All U Get

Looks good. Mine is even simpler - I lag bolted a 2 by 6 across two nearby 4X4 support posts in our basement/crawl space, and hang my Honda 8 on that. I can slide a plastic garbage can under the leg to test run it in water. Works fine if you have robust support posts that are near enough, say 3 to 4 ft separation.

Nice... Great Idea. Searching DIY outboard stands I saw this on Google Images. Love the simplicity and cheap materials.

JL Stratton

What a wonderful idea. I'm definitely going to steal this idea. Sure beats laying the motor on the ground.

Im glad its helpful. I think it took less than 6' per stand using a 2" x 12".

Nice.

What's next, bird houses? All U Get

All U Get said: What's next, bird houses? All U Get Click to expand

Is there nothing to prevent it from falling sideways?

Crazy Dave Condon

I used discarded 55 gallon drums at time for stands with one no holes in it filled with water to run engines in it. If outside you might want to drill holes to drain rain water. Use to paint mine and one was hot pink just for laughs.

Ron20324 said: Is there nothing to prevent it from falling sideways? Click to expand

I am going to copy your design, Thanks.

Thanks for the idea, works great.

I made mine out of an old hand truck, some U Bolts, and a chunk of 2x12.

I was lucky. The basement of our vacation house has 4 by 4 posts supporting the floor above, and one pair are about 3 ft apart. I lag bolted a 1 by 6 (or similar) across them, and mount the motor on that, and put a shelf on one post to support the fuel tank. It is the proper height to put a garbage can under it so I can test run it (yeah, it does get some fumes in the basement but I leave the door open and don't run it long).

pateco said: I made mine out of an old hand truck, some U Bolts, and a chunk of 2x12. Click to expand

Will Gilmore

You're design has a great modern aesthetic that I really like. You might consider adding some type of cross grain support to help prevent the 2x12 from splitting as it ages and dries out. I really like the addition of the casters. -Will (Dragonfly)

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

- Drawing And Sketching

- Free Crochet Patterns

- DIY Projects

- DIY Automotive

- DIY For Pets

- Kitchen organizing

- Tie Dye Projects

- Modern Footer

18 DIY Boat Stands For Kayak

Published: Nov 27, 2021 · Modified: Oct 19, 2023 by Tijasar · This blog generates income via ads

Just because you own a boat, it doesn’t mean you have to have a fancy modern dock for it. Dropping the boat on the ground or on a bunch of wooden boards can certainly hold it in place while you’re working with your boat, but it’s bad for the boat and not very convenient. Spending all day dropping and picking up the boat whenever you want to use it isn’t any fun either; that’s why many people instead turn to backyard boat stands. We've come up with 18 DIY Boat Stands for Kayaks that are both strong and simple to make. Most of the boat stands are made out of wood but you can adapt them to use PVC pipe, steel, or even cinder blocks if you're up to the challenge.

DIY Boat Stands:

As you are searching the internet for the perfect DIY boat stand, you are definitely going to need some help. That’s why we have created this list of 18 DIY Boat Stands for Kayaks that will make your life a little bit easier. This way, instead of spending hours looking at options on your own, you can more easily pick one option of the eighteen available, make your boat stand, and enjoy yourself on the water with friends and family!

Kayak Stands

Get your kayak off the ground and keep it safe with kayak stands. Use two kayak stands to make up a storage rack for your kayaks, or use one kayak stand in your boat shed to keep your boat off the floor. Storage racks make transporting your boat easy too. Many racks carry multiple boats at once. Kayak stands come in many different materials, including plastic, aluminum, and toe-kick legs. Some kayak stands are portable so you can take them with you on your next trip!

How to Build an A-Frame Kayak Rack

Looking for a way to store your new A-Frame kayak securely while also keeping it visible? This article will give you the basics and show you how to build your very own A-frame kayak carrier. All you'll need is a few tools and some spare wood scraps. Maybe you've got an older one still in great shape but no longer fit for storage on the water, and don't want to throw it away. No problem! This really easy-to-follow guide takes you through constructing an A-frame kayak rack that will not only look good but also last for many years. Great gift idea!

Making A Cheap Boat Stand

This Instructable will provide you with the details you need to build a boat stand out of shipping pallets. It is intended for use in conjunction with an existing hoist-style safety stand. The simple design should make this project budget-friendly, and allow you to safely store your boat. This design will give you an inexpensive alternative to commercial boat stands. The design can be modified for your specific needs by using different sizes of pipe or varying the length of the cross beams.

DIY Kayak Stand

The DIY Kayak Stand is easy to assemble! The table of contents makes it easy to get to the right chapter for each topic. It is recommended that you watch the Basic Instructions video on this page before beginning your work. This video will be seen in its entirety once, so if you are printing it, be sure not to start at the top of the numbered pages.

Your kayak deserves a stand that is both portable and versatile. This Instructable will teach you how to build a stand with limited tools and cost. The stand can hold kayaks of varying sizes, with little support needed from you, freeing your hands for the gear.

How To Make A Boat Cradle

Get rid of those ropes or tie-downs that keep your boat moored to a tree. Here is another simple boat cradle, or you can instead call it a boat cradle. It is made up of two parts, one at the front of the boat, and the other at the back, holding the entire weight of them efficiently. To make a boat cradle, you're going to need two people. The first person holds the boat by the bow, and the second person stands higher up on the beach, facing the direction of the wind. Then hoist the boat onto this second individual. This method is useful when dealing with larger boats, as it is easier to handle them using another person's help.

DIY Portable Kayak Boat Stand

Sometimes you don’t know what to do with your kayak or canoe. You don’t have enough time to transport it, or you have enough time but you don’t have the strength to carry it around by yourself. This portable kayak boat stand is easy to fold and convenient to carry around from one place to another. With it, you can carry your boat comfortably wherever you go.

Boat Stand Quick Build DIY

There are a lot of plans you could make use of, but here is a simple boat stand plan to get you started. This boat stand will help you to do away with the hassles of storing your boat, and it will also allow you to service your boat at its side. What’s more? It can fit any size of boat. This plan will be really simple for any person who possesses basic woodworking skills and tools. With that said, this plan uses many materials that one could find within their local hardware store. The important thing about this plan is to set the right dimensions and follow the steps described in this guide.

DIY 5 Minute Canoe Stand

Looking for an easy project to make in under 5 minutes? We can help. This DIY canoe stand is made with only 3 steps and will make your life a bit easier when it comes to storing or displaying your canoe. The legs of this stand come at separate prices depending on the store, but the materials are still relatively affordable. This DIY Stand will help you store your canoe in less than 5 minutes without taking up too much space.

How To Make A Cheap Boat Stand

Want to make a simple yet practical boat stand? Why not try this! You could easily make this stand by utilizing scrap materials like plywood and steel. It could be the best boat stand that you've ever made because it incorporates handrails, wheels, and bearings. It is sturdy, durable, cheap, and easy to build. All you need to do is get hold of the required materials and tools. The attached wheels make it ideal for indoor use as well as outdoor use.

DIY Boat Stand Plan

Build your own boat stand easily with the help of this guide! The creator has provided easy-to-understand directions for this quick and easy project. He used simple materials that are inexpensive and can be found in your local home center or hardware store. This boat stand is sturdy and will allow safe storage of many standard-size watercraft while being able to wheel it around easily. It is also very easy to move around whenever you want to shift the boat into another place.

DIY Bait Boat Stand

What do you need to make your own DIY bait boat stand? This easy boat stands DIY project is great for storing bait in the garage or shed. You don’t need to use a large stand if you have just one little boat. This stand uses three wooden boards, wood glue, and a drill to put together in no time. It's easy to make, inexpensive, and very functional.

Mobile Jon Boat Stand DIY

Well here is something special. Most Boat stands are pretty expensive and this one is quite the opposite. This boat stand is mobile because it features wheels at the end of it that you can move out to get your boat in or out of your garage. The creator used wood for the construction which is the most budget-friendly material to work with. They did not go all out with paint though, they just gave it two coats of water-based primer and black paint. So if you’d like to get yours done or learn more about doing so, check out this Instructables Page. Good luck!

DIY RC Cheap Boat Stand

If you own an RC boat you know how easily they take damage off the ground. This simple and sturdy stand will hold your boat up perfectly and keep it safe from dust and water. The stand can be altered to fit any size of RC boat so no need to worry about changing it!

This DIY RC boat stand is easy to make and costs very little. At the end of the video, you will be given instructions on exactly how to make your own RC boat stand.

DIY Boat Motor Stand

Here is an easy-to-make DIY boat motor stand that you can build with ease. The basic materials required for this project are wood, a tape measure, a miter saw, and some common woodworking tools. The basic materials needed are wood, a miter saw, and other woodworking tools. With these tools and this design, you can build your own motor stand in just one day.

DIY Cheap Kayak Stand

If you are a person who likes to escape to nature, relaxing on a kayak is something that can help you spend time doing what you are most passionate about. It’s also a great exercise to have some fun out in the open, enjoying the warm sun rays with your best friends. Whether you are a beginner or not, whether it’s your first kayak or not, we all know how hard it can be to find ways to carry and store it and certainly take it stably and securely to the water. Our DIY cheap kayak stand will make setting up your boat simple and quick.

Semi DIY Boat Stand

It’s not that there isn’t enough room in your garage to store your boat, but you just can’t fit it inside the house due to tight space between the front door and the back door of your home. Furthermore, you need secure storage for your boat so it wouldn’t be very useful if you do leave it outside. This is where this DIY boat stand would come in handy. You can use two director folding chairs for this project. By stripping the chairs of their seat cushions, you can use them as planks on which you can stand your boat vertically in between.

Fishing Boat Storage Stand

This Fishing Boat Storage Stand is a quick and easy DIY project capable of supporting a small boat for outdoor storage. The stand can also be used as a workbench, as it provides a seat for those projects requiring a seat. It measures five feet long, which is large enough to accommodate most offshore fishing boats as pictured above or smaller craft such as kayaks. Cut list and step-by-step instructions are provided.

DIY Boat Rack

Build your own boat rack with these easy-to-follow instructions and free downloadable plans and guides. A boat is a wonderful thing to own, but what do we do when we get home from a day on the water? One way to make sure we can get out on the lake at a moment's notice is to build or have someone build for us, a boathouse. Here are some tips and tricks for building your own DIY boat rack that will work just perfectly for storing your canoe or kayak.

simplifiedbuilding

More DIY Projects

Sharing is caring!

- Pinterest 8

DIY Outboard Motor Stand Plans and Tips

When it comes to owning and maintaining boats, having the right equipment can make all the difference. One such essential piece of equipment is an outboard motor stand. Whether you’re a seasoned boater or just starting out, having a sturdy stand to securely hold and work on your outboard motor is invaluable. Not only does it provide a safe and convenient way to store your motor when not in use, but it also makes maintenance and repairs much more manageable.

In this article, we’ll take a DIY approach to building your own outboard motor stand. Why DIY? Well, not only does it allow for cost savings, but it also gives you the freedom to customize the stand to perfectly fit your motor’s specifications. We’ll provide comprehensive plans and step-by-step guidance to help you create a reliable and tailored outboard motor stand, ensuring that your boating experiences remain smooth and hassle-free.

Understanding the Need for an Outboard Motor Stand

An outboard motor stand is an indispensable piece of equipment for boat owners, serving various crucial purposes:

- Safety and Damage Prevention: Storing your outboard motor on the ground, a trailer , or any uneven surface can expose it to numerous risks. Moisture, dirt, and pests can damage sensitive engine components. Additionally, placing it directly on concrete or rough surfaces can lead to scrapes, dents, or even structural damage.

- Convenient Maintenance: Maintenance and repairs are inevitable in the life of an outboard motor. Having a dedicated stand allows you to securely place the motor at a comfortable working height. This simplifies tasks like changing the oil, inspecting and repairing propellers, and conducting routine check-ups, significantly reducing the risk of injury and simplifying the process.

- Space Efficiency: Storing a motor on a stand makes efficient use of space. You can easily tuck it away in a garage, workshop, or even a corner of your boat shed. This organized storage not only saves space but also prevents clutter and tripping hazards.

- Longevity: Proper storage and maintenance prolong the life of your outboard motor, which is a significant investment for any boat owner. By using a stand, you minimize exposure to damaging elements and ensure the motor remains in top condition for years to come.

An outboard motor stand is not just a convenience; it’s a safeguard for your investment, offering protection, accessibility, and longevity for your motor.

List of Materials and Tools Needed for the Project

Building your own outboard motor stand requires some basic materials and tools to ensure a sturdy and functional result. Here’s a list of what you’ll need:

- Wood: Opt for sturdy and durable wood, such as plywood or lumber boards. The exact amount will depend on your design, but having extra is always helpful.

- Screws: Get a variety of screws, including wood screws for securing pieces together.

- Brackets: Metal brackets or corner braces will add extra stability to your stand.

- Nails: You might need these for additional reinforcement.

- Measuring Tape: For precise measurements.

- Pencil or Marker: To mark measurements and cut lines on the wood.

- Sandpaper: Smooth any rough edges or surfaces.

- Paint or Finish (Optional): To protect the wood and improve the stand’s appearance.

- Circular Saw or Jigsaw: For cutting the wood to the desired lengths and shapes.

- Drill and Drill Bits: Essential for making holes for screws.

- Screwdriver: To tighten screws securely.

- Sawhorses (Optional): They can be helpful for supporting long pieces of wood during cutting and assembly.

- Safety Gear: Wear safety glasses and hearing protection, especially when using power tools.

- Workbench or Table: A flat, stable surface for assembly.

Make sure to gather all these materials and tools before you start your DIY outboard motor stand project. Having everything ready will make the construction process smoother and more efficient.

Designing Your Outboard Motor Stand

When designing your DIY outboard motor stand, it’s essential to consider several factors to ensure it’s the right fit for your specific outboard motor. Here are some design considerations:

- Motor Dimensions: Measure the length, width, and height of your outboard motor. The stand’s dimensions should accommodate the motor without any overhang, ensuring a secure fit.

- Weight Capacity: Determine the weight of your outboard motor. Your stand should be designed to comfortably support this weight. Consider a safety margin to ensure stability.

- Mounting Points: Decide how your motor will be secured to the stand. Typically, this involves creating a cradle or bracket that matches the motor’s mounting points. Ensure the stand’s structure can support these attachment points securely.

- Stability: Design the stand to be stable and well-balanced. A wide, sturdy base will prevent tipping. Consider adding cross bracing or support beams to enhance stability.

- Adjustability (Optional): If you have multiple outboard motors with different sizes, you might want to design an adjustable stand. This allows you to modify the stand’s dimensions to accommodate various motors.

- Mobility (Optional): Depending on your needs, you can add wheels or casters to the bottom of the stand to make it easier to move around your workspace.

- Materials: Choose high-quality, sturdy materials like plywood or lumber that can bear the weight of your motor. If you’re concerned about moisture or outdoor storage, consider pressure-treated wood or marine-grade plywood.

- Paint or Finish (Optional): Applying a finish or paint can help protect the wood from moisture and environmental factors, ensuring the stand’s durability.

- Safety: Ensure there are no sharp edges or protruding screws that could cause injury during use. Sand down any rough spots.

- User-Friendly: Make sure your design allows for easy access to all parts of the motor, so you can perform maintenance and repairs without hindrance.

Remember that your design should match your specific outboard motor’s dimensions and weight. Building a stand that is tailored to your motor’s specifications will ensure a safe and secure storage and maintenance solution.

Step-By-Step Guide to Building Your Outboard Motor Stand

Building your DIY outboard motor stand is a rewarding project. Here’s a step-by-step guide to constructing a sturdy and reliable stand:

Materials You’ll Need:

- 4×4 lumber for the legs

- 2×4 lumber for the frame and support beams

- Plywood for the base and motor support

- Screws, bolts, and nuts

- Measuring tape

- Circular saw or miter saw

- Drill and drill bits

- Wrenches and socket set

- Safety gear (goggles, gloves, ear protection)

Let’s start building

- Step 1: Design Your Stand Before you begin, have a clear design plan based on your outboard motor’s dimensions. Ensure you have enough space to comfortably accommodate the motor without any overhang.